JM23 brick have become a hot-selling product in the refractory market due to their excellent performance and wide application. With the continuous increase in sales, more and more customers choose JM23 bricks for various high-temperature industrial equipment.

Hot-selling JM23 brick

JM23 bricks have achieved significant success in the market, with sales continuing to grow. This is mainly due to the following characteristics:

- Excellent thermal insulation performance: JM23 insulation bricks have low thermal conductivity, which can effectively reduce heat loss and improve energy utilization efficiency.

- High-temperature stability: JM23 bricks can maintain good structural strength and chemical stability in high-temperature environments.

- Good thermal shock resistance: able to withstand rapid temperature changes without cracking or damage.

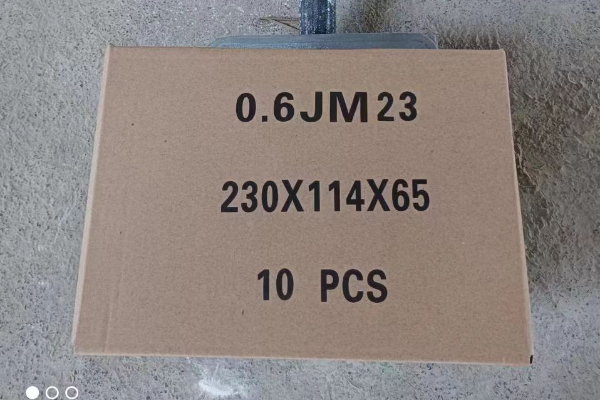

- Easy to process and install: JM23 bricks are standard in size, easy to cut and install and adapt to various complex construction environments.

JM23 brick production process

Raw material preparation

Material selection: Select high-purity refractory clay, alumina and other auxiliary materials.

Testing: Test the chemical composition and physical properties of raw materials to ensure that they meet production standards.

Raw material handling

Crushing and grinding: The bulk raw materials are crushed and then further ground to the required fineness by ball mill or Raymond mill.

Forming

Pressing and molding: Place the evenly mixed mud in a mold and press it under high pressure to form a brick.

Drying and calcining

Drying: Use a drying room or kiln to accelerate the drying process of the bricks through a heating and ventilation system.

Firing: The kiln gradually heats up, passing through three stages: low temperature, medium temperature and high temperature, and is kept at the highest temperature for a period of time to ensure that the bricks are fully sintered.

Kiln unloading and inspection

Unloading and inspection: After the kiln cools down to room temperature, the fired JM23 bricks are taken out for appearance inspection and physical property testing.

Rongsheng Group

Rongsheng Group

WeChat

Scan the QR Code with wechat