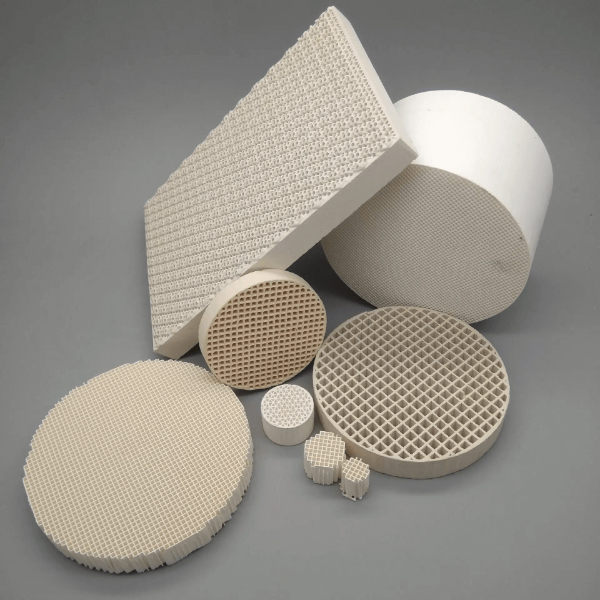

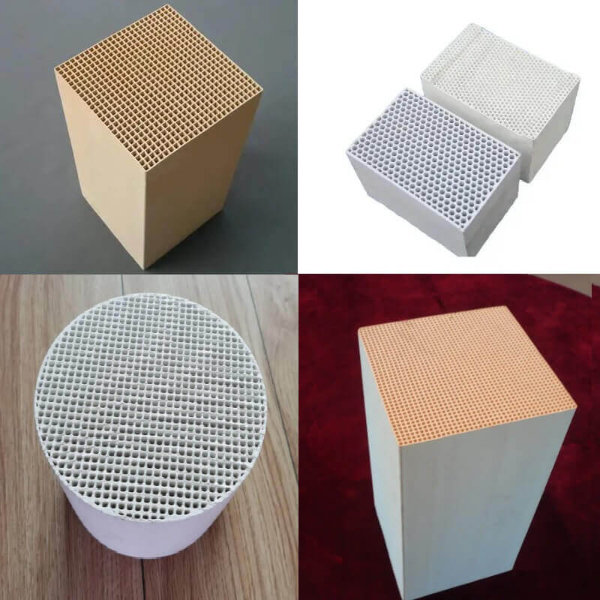

Ceramic honeycomb block refractory material is a type of special ceramic material with high-temperature stability and excellent fire resistance. Its unique honeycomb structure gives it lightweight, high strength, and excellent heat and sound insulation properties, making it widely used in harsh environments such as high temperatures and corrosion. The basic characteristics, preparation process and main application fields of ceramic honeycomb refractory materials will be introduced below.

Characteristics of ceramic honeycomb

- Honeycomb structure. Ceramic honeycomb block refractories are named for their honeycomb-like structure, which has a very high specific surface area, which improves its adsorption and reaction properties.

- High-temperature stability. This type of refractory material is usually based on high-temperature ceramic powder and sintered at high temperatures. It has excellent high-temperature stability and can maintain stable performance in extremely high-temperature environments.

- Excellent heat insulation and sound insulation performance. The unique structure of the ceramic honeycomb block makes it outstanding in thermal and sound insulation, making it suitable for environments where heat and sound conduction need to be controlled.

The production process of ceramic honeycomb

- Material preparation. High-quality ceramic powder is selected as the basic material, and a certain proportion of stabilizers, binders, and other auxiliary materials may be added according to specific needs to ensure that the ceramic honeycomb body produced has the required performance.

- Molding. Molding processes such as extrusion and injection molding are used to shape the material into a green body with a honeycomb structure.

- Sintering. Through the high-temperature sintering process, the formed body is turned into a dense and hard ceramic material, improving its high-temperature stability.

- Surface treatment. Depending on specific needs, ceramic honeycomb blocks are surface-coated or otherwise specially treated to enhance their specific properties.

Application fields of ceramic honeycomb

- Steel smelting. Thermal and sound insulation linings are used in high-temperature furnaces to protect the furnace structure from high-temperature corrosion.

- Chemical industry. They are used for equipment lining in high-temperature and highly corrosive environments such as oil refining and petrochemicals to protect equipment from corrosion.

- Green facilities. As a filter material for flue gas purifiers, it is used to remove particulate matter and harmful gases in industrial waste gas.

- Thermal equipment. It is used as the insulation layer of high-temperature equipment such as boilers and kilns to improve the thermal energy utilization efficiency of the equipment.

- Energy industry. As a key component of energy devices such as fuel cells, it provides a stable electrolyte carrier

Rongsheng Group

Rongsheng Group

WeChat

Scan the QR Code with wechat