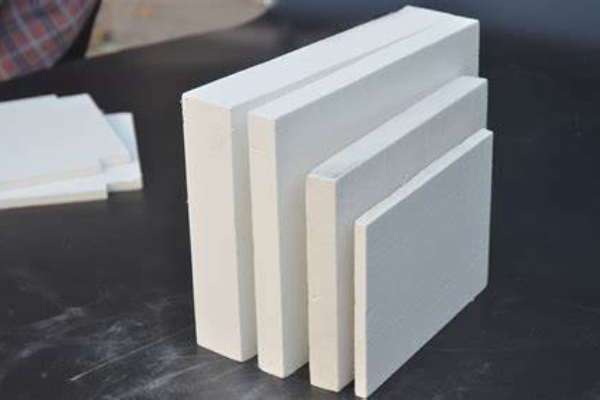

El tablero refractario de cerámica se usa ampliamente en campos industriales de alta temperatura, como la metalurgia., petroquímico, energía eléctrica, horno, etc.. due to its high-temperature resistance, Excelente aislamiento térmico y resistencia a la corrosión. Sin embargo, Durante el almacenamiento o uso, some users may find that the surface of ceramic fiberboard turns yellow or changes color. This not only affects the appearance but also may affect its performance. Entonces, why does the ceramic fiberboard turn yellow? And how can we prevent it?

The main reason for the yellowing of ceramic fiberboard

- The yellowing of ceramic fiberboard is mainly caused by the crosslinker and tackifier in the neutral glue. The reason is that these two raw materials contain “amine groups”, which are very easy to cause yellowing.

- If the external neutral transparent glue is used at the same time as the acidic glass glue, it may cause the neutral glue to turn yellow after curing.

- It may be caused by the long storage time of the glue or the reaction between the glue and the substrate.

- Moisture or oxidation. If the ceramic fiberboard is exposed to a humid environment during storage, it will absorb moisture in the air and react with trace metal impurities to cause the surface to turn yellow. Además, acidic or alkaline gases in the air may also accelerate the oxidation process.

- High-temperature oxidation reaction. When used in a high-temperature environment, the ceramic fiberboard may absorb smoke, and oxides or undergo oxidation reactions, causing the color to gradually turn yellow or even black. Especially in high-temperature industries such as metallurgy and petrochemicals, if the flue gas contains sulfur dioxide (SO₂), carbon monoxide (CO), and other gases, it may also react chemically with the surface of the fiberboard, causing color changes.

- Influence of transportation and storage environment. If the ceramic fiberboard is not sealed during transportation or storage, it may be contaminated by dust, oil or chemicals in the air, causing the surface to turn yellow. Además, ultraviolet rays in the sun may also cause certain chemical components to decompose, causing color changes.

Does the yellowing of ceramic refractory board affect its use?

En general, the yellowing of ceramic fiberboard is mainly a surface phenomenon. If the material has not changed and still has the original thermal insulation and fire resistance, it can be used normally. Sin embargo, if the discoloration is serious, accompanied by fiber brittleness, reduced strength or powdering, it may be that the material is aging or contaminated, and needs to be replaced in time to ensure the safety and stability of the project.

Grupo Rongsheng

Grupo Rongsheng

WeChat

Escanea el código QR con wechat