Anchor bricks play the role of skeleton in refractory castables. Anchor bricks are also called hanging bricks.

Anchor product introduction

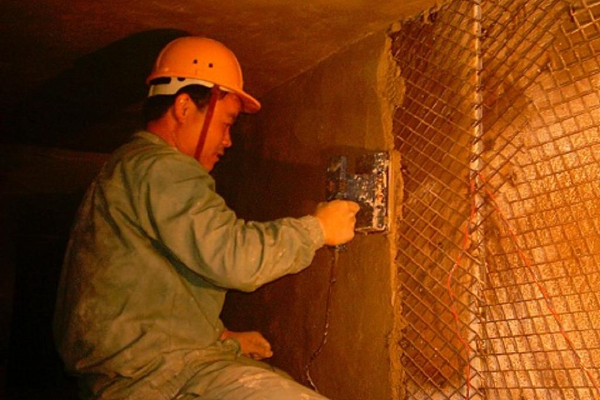

내화 캐스터블의 뼈대 역할을 하는 제품은 여러 가지가 있습니다.: 하나는 앵커 벽돌입니다, 다른 하나는 앵커입니다, 세 번째는 대모갑 메쉬입니다. Anchors and tortoiseshell mesh are both metal products, and only anchor bricks are refractory products.

Introduction to anchor bricks

Anchor fire bricks come in many shapes and ways of linking and come in a variety of sizes. 일반적으로, they are made according to user customization. Some common lengths are 330, 380, 440, and 500m; the thickness of the anchor bricks is about 100mm, and their function is to act in the refractory castable lining.

There are differences between anchor fire bricks with holes and without holes, and there are differences between the use of holes and the usefulness of furnace roofs and furnace walls. They are either embedded in castables or hung with hanging parts, so they can also be called hanging bricks.

Anchor introduction

The anchors are directly welded to the furnace shell. When the refractory castable is poured, the anchors are embedded in the lining to serve as anchors and connections. The most commonly used ones are Y, V, and L shapes. The height is determined according to the thickness of the refractory castable. If the thickness of the castable is 200mm, the height of the anchor can be 160-180mm. Anchors are easily oxidized at high temperatures. When embedding the castable lining, the thickness of the lining and the operating temperature should be determined.

Anchor bricks production process

Anchor brick is a refractory brick that is reshaped and sintered after raw material technology proportioning. They have high strength, 좋은 열충격 안정성, and toughness. 하지만, the mold for anchor bricks is a difficult point in the production process. The grinding tools are complicated and difficult to make, and the mold cost is much higher than that of ordinary refractory bricks.

Installation location of anchor refractory bricks

If the anchor brick has holes, the installation holes are usually in the neck. The finished anchor bricks must have no cracks and must be accurate in size. Convenient for stovetop use. Anchor fire bricks generally use third-grade high-aluminum anchor bricks because third-grade high-aluminum anchor bricks have toughness. Although the first-grade high-alumina bricks are of good quality, their hardness also increases, and cracks are prone to occur when used in ordinary castables. Anchor fire bricks play the role of skeleton connection in the pouring of castables. They are produced according to user requirements, but they must not have cracks. If cracks appear, they will easily fall and affect the use of refractory castables.

영성그룹

영성그룹

위챗

wechat으로 QR 코드를 스캔하세요