실리콘 카바이드 분말은 육각 결정입니다, 안정적인 화학적 특성, 높은 열전도율, 작은 열 팽창 계수, 좋은 내마모성, 그리고 Mohs의 경도 9.5. 그것은 검은 색과 녹색의 두 가지 기본 품종을 가지고 있습니다. 검은 실리콘 카바이드 분말은 강인성이 좋습니다, 유리 산업에서 널리 사용됩니다, 세라믹 산업, 석재 산업, 내화물 산업, 철 산업, 비철 산업, 등. 녹색 실리콘 카바이드 분말은 자체 공유가 좋습니다, 주로 하드 합금 처리에 사용됩니다, 티타늄 합금,와이, 그리고 광학 유리, 또한 실린더 라이너를 연마하고 정확한 연삭 HSS 도구.

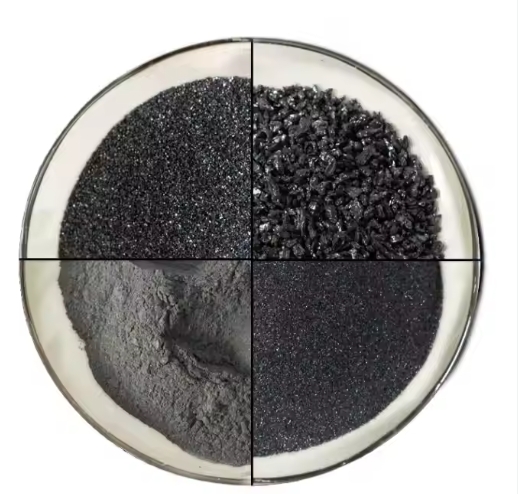

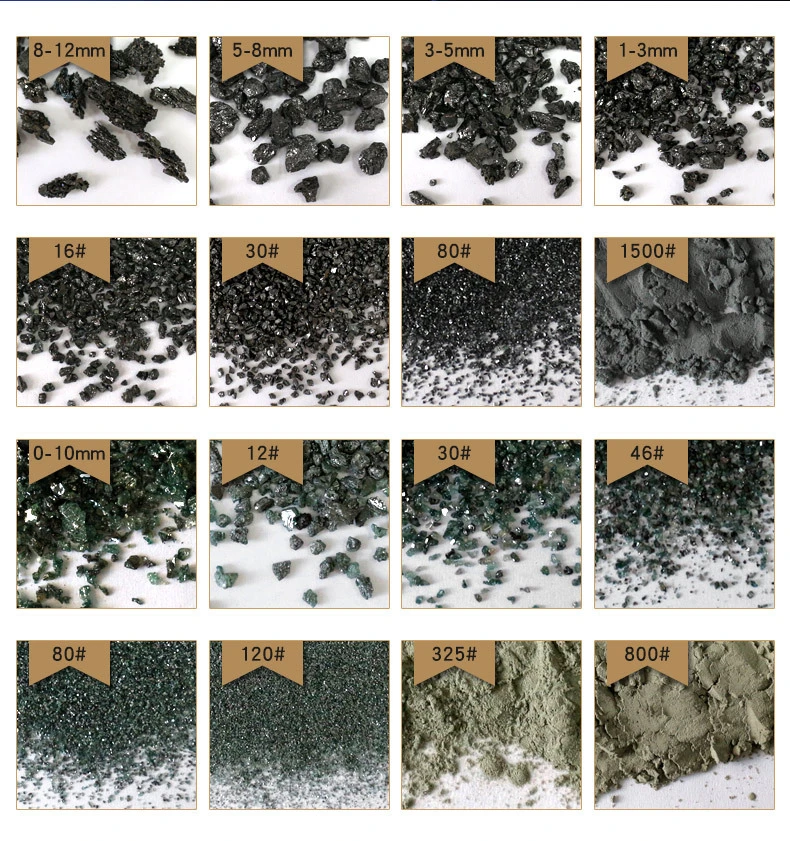

검은 실리콘 카바이드 분말 및 녹색 실리콘 카바이드 분말

다른 용도에 따라, 실리콘 탄화물은 검은 실리콘 카바이드와 녹색 실리콘 카바이드로 나눌 수 있습니다..

검은 실리콘 카바이드: 더 많은 것을 포함합니다 99% SIC 및 주로 내화성 재료에 사용됩니다, 연마재, 등.

녹색 실리콘 카바이드에는 더 많은 것이 포함되어 있습니다 99.5% sic은 순도가 높다. 주로 세라믹 및 반도체 제조에 사용됩니다.

실리콘 카바이드 원료의 기술 매개 변수

| 색상 | 과립성 범위 | 화학 성분 % | 밀도 G/CM3 | ||

| SiC | F.C | 철2영형3 | |||

| 검은색 | F4 ~ F90/P12 ~ P100 | ≥98.6 | ≤0.2 | ≤0.4 | ≥3.12 |

| F100 ~ F150/P120 ~ P150 | ≥98.1 | ≤0.25 | ≤0.5 | ||

| F180 ~ F220/P180 ~ P220 | ≥97.2 | ≤0.3 | ≤0.55 | ||

| F230 ~ F280/P240 ~ P360 | ≥97.2 | ≤0.3 | ≤0.55 | ≥3.10 | |

| F320 ~ F500/P400 ~ P1000 | ≥97.0 | ≤0.35 | ≤0.6 | ||

| F600 ~ F800/P1200 ~ P1500 | ≥96.5 | ≤0.4 | ≤0.6 | ||

| F1000 ~ F1200/P2000 ~ 2500 | ≥95.5 | ≤0.5 | ≤0.7 | ||

| 녹색 | F4 ~ F90/P12 ~ P100 | ≥99.1 | ≤0.2 | ≤0.2 | ≥3.18 |

| F100 ~ F150/P120 ~ P150 | ≥98.6 | ≤0.25 | ≤0.45 | ||

| F180 ~ F220/P180 ~ P220 | ≥98.0 | ≤0.25 | ≤0.5 | ||

| F230 ~ F280/P240 ~ P360 | ≥98.0 | ≤0.3 | ≤0.5 | ≥3.15 | |

| F320 ~ F500/P400 ~ P1000 | ≥97.5 | ≤0.3 | ≤0.5 | ||

| F600 ~ F800/P1200 ~ P1500 | ≥97.0 | ≤0.35 | ≤0.5 | ||

| F1000 ~ F1200/P2000 ~ P2500 | ≥96.5 | ≤0.4 | ≤0.5 | ||

실리콘 카바이드 분말의 기본 특성

높은 경도 및 높은 내마모성: MOHS 경도는 9.2 ~ 9.5만큼 높습니다, 이상적인 내마모성 재료로 만듭니다.

높은 열전도율: 열전도율은 120 ~ 270 w/m · k만큼 높습니다, 우수한 열전도율로.

고온 안정성: 우수한 고온 저항, 1600 이상의 환경에서 오랫동안 안정적으로 사용할 수 있습니다..

높은 부식 저항: 산 및 알칼리 부식에 대한 강한 저항, 가혹한 화학 환경에 적합합니다.

우수한 열 충격 안정성: 온도가 상승하거나 빠르게 떨어지면 열 충격 손상을 효과적으로 저항 할 수 있습니다..

제어 가능한 전기 특성: 전도도와 단열재가 있으며 반도체 필드에서 널리 사용됩니다..

실리콘 카바이드 분말의 적용 분야

불응 성 물질

SIC는 내화 벽돌을 제조하는 데 중요한 원료입니다., 캐스터블, 고온 및 부식 저항으로 인한 세라믹 선박. 야금과 같은 산업의 고온 가마 안감에서 널리 사용됩니다., 유리, 그리고 시멘트.

연마제 및 절단 도구

SIC는 연삭 휠과 같은 도구를 만들기위한 높은 경도로 인해 연마제로 사용됩니다., 연삭 디스크, 갈기 머리. 유리와 같은 단단한 재료를 자르는 데에도 사용됩니다., 세라믹, 그리고 보석들.

반도체 재료

3 세대 반도체 재료로서, SIC에는 넓은 밴드 갭의 특성이 있습니다, 높은 고장 전기장, 높은 열전도율. 전기 자동차에 널리 사용됩니다, 5G 커뮤니케이션, 광전지 인버터,,S 및 MOSFET과 같은 전원 장치를 제조하기위한 기타 필드, 위로, t와 다이오드.

화학 장비

SIC 재료는 부식에 매우 강합니다, 그래서 그들은 열교환기로 사용됩니다, 원자로 안감, 펑크,피, 화학 산업의 밸브 부품, 특히 강산을 처리하는 데, 강력한 알칼리 및 고온 부식성 매체.

새로운 에너지 기술

태양 광 및 풍력 전력 장비, SIC는 열 교환 요소 및 인버터 장치로 사용됩니다.. 고효율과 높은 내구성은 새로운 에너지 장비의 안정적인 작동을 보장합니다..

항공 우주 및 군사 산업

SIC는 고온 저항성 및 산화 방지 항공 우주 장비 부품을 제조하는 데 사용됩니다., 터빈 블레이드 및 미사일 코 원뿔과 같은, 가볍고 강도로 인해.

영성그룹

영성그룹

안녕하세요,

입자 직경이 1~3mm인 탄화 규소 분말에 관심이 있습니다.. 유럽 연합 내에 대리점이 있습니까?? 이렇게 하면 배송이 더 쉬워질 거예요! 나는 독일에 거주하고 있습니다..

안녕하세요, 우리는 귀하의 문의를 받아 매우 기쁘게 생각합니다. 당사의 비즈니스 관리자가 귀하에게 연락하여 실리콘 카바이드의 배송 세부 사항을 논의할 것입니다.. 이메일을 확인해주세요.