Our company is honored to announce a successful cooperation with a major metallurgical company in Ecuador to provide it with high alumina bricks and low cement mullite castables, which have been successfully delivered. The following are case details of this cooperation:

Ecuador customer introduction

The Ecuadorian customer is a metallurgical materials company, a well-known metallurgical industry company in Ecuador. The customer contacted us and wanted to purchase a batch of refractory materials.

Order details

Prodotti: High alumina bricks and low cement mullite Casflitte

Specifications: Mattone ad alto contenuto di allumina – 230mm x 114mm x 65mm, Low Cement Mullite Castable – Customized Specifications

Quantity: 200 tons of high alumina bricks, 150 cubic meters of low cement mullite castables

Delivery time: 8 weeks

Delivery location: By sea to major ports in Ecuador

Purpose of purchasing high alumina bricks and low cement mullite castables

Ecuador Metallurgical Co., Ltd. is a leading company in the metallurgical industry in Ecuador, focusing on the production of metal smelting and related processes. They urgently need high-quality refractory materials for lining and insulation of their high-temperature smelting furnaces. High-alumina bricks were selected as the lining material due to their excellent fire resistance and corrosion resistance, while low-cement mullite castables were used for the thermal insulation layer to ensure the stable operation of the equipment at high temperatures.

We have reached a cooperation

Demand confirmation: Our company conducted in-depth technical exchanges with customers to understand their specific needs for refractory materials, and provided solutions for high-aluminum bricks and low-cement mullite castables suitable for high-temperature smelting furnaces.

Sample testing: In order to ensure that the product meets the customer’s technical specifications and quality standards, our company provides samples for strict testing and is recognized by the customer.

Contract Negotiation: The two parties negotiated in detail on the order quantity, specifications, delivery time and price, and signed a formal contract.

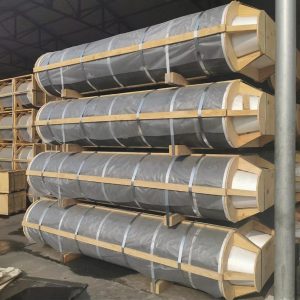

Production and quality inspection: Our company starts production in accordance with the requirements stipulated in the contract, and conducts strict quality control during the production process to ensure that the products meet the standards.

Sea transportation and delivery: After production is completed, the products are professionally packaged and labeled, and delivered on time by sea to the port designated by the customer in Ecuador.

Gruppo Rongsheng

Gruppo Rongsheng

WeChat

Scansiona il codice QR con wechat