The main raw materials of steel ladle slide gate plate is aluminum carbon and aluminum zirconium carbon. The need for special steel diversifies the development of slide plates. Sliding plate brick has the advantages of high fire resistance, Buona stabilità chimica, slag and liquid metal corrosion resistance, good oxidation resistance, and spalling resistance.

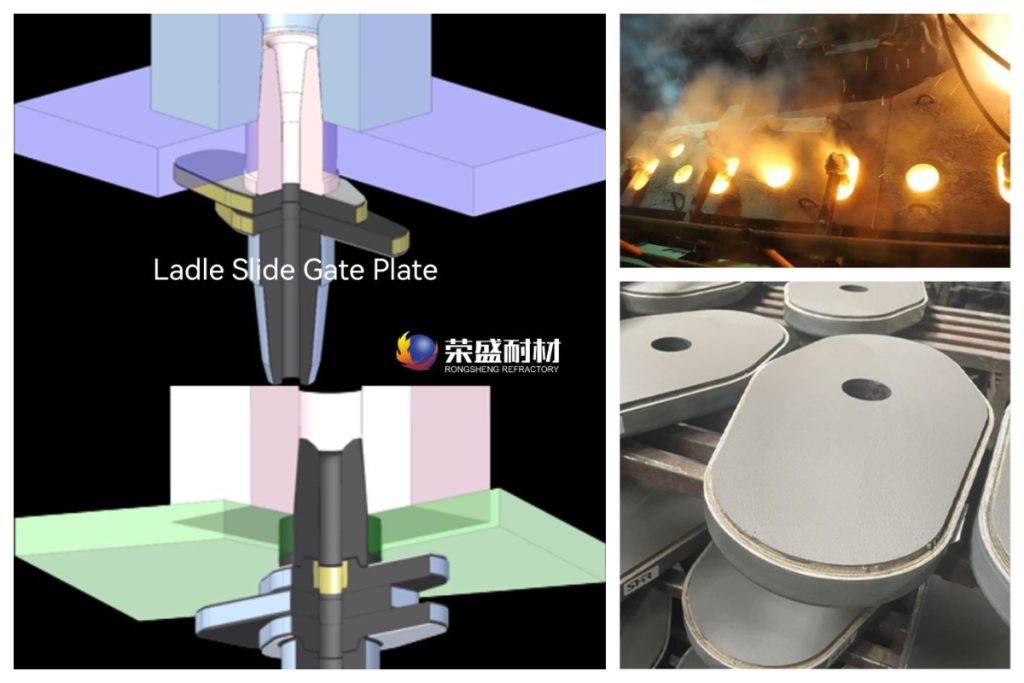

Ladle slide plate introduction

The ladle slide plate is suitable for large and medium-sized ladles and continuous casting steel mills. It can meet the production needs of different steel grades. The sealing protection of the ladle sliding nozzle is mainly at the connection between the upper nozzle and the upper slide plate, and the lower slide plate and the lower nozzle.

Technical Parameter of steel ladle slide gate plate

| Articolo | Indice | |||

| HBLT80 | HBLT75 | HBLT70 | ||

| Al2O3 % | ≥80 | ≥75 | ≥70 | |

| C % | ≥2 | ≥3 | ≥3 | |

| MPA di forza di schiacciamento freddo | Nonimpregnation | ≥80 | ≥70 | ≥60 |

| Impregnation | ≥100 | ≥90 | ≥80 | |

| Porosità apparente% | Non-impregnation | ≤13 | ≤13 | ≤13 |

| Impregnation | ≤10 | ≤10 | ≤10 | |

| Densità apparente g/cm3 | Non impregnation | ≥2.9 | ≥2,85 | ≥2.75 |

| Impregnation | ≥2,95 | ≥2.9 | ≥2,85 | |

Aluminum Zirconium Carbon:

| Articolo | Indice | ||||

| HBLTG80 | HBLTG75 | HBLTG70 | HBMLT80 | ||

| Al2O3 % | ≥80 | ≥75 | ≥70 | / | |

| Al2O3+MgO % | / | / | / | ≥80 | |

| C % | ≥3 | ≥3 | ≥4 | ≥3 | |

| ZrO2 % | ≥4 | ≥4 | ≥4 | / | |

| Porosità apparente% | Non-impregnation | ≤13 | ≤13 | ≤13 | ≤13 |

| Impregnation | ≤10 | ≤10 | ≤10 | ≤10 | |

| Bulk density g/cm3 | Non-impregnation | ≥3,0 | ≥2,95 | ≥2.9 | ≥2.75 |

| Impregnation | ≥3.05 | ≥3,0 | ≥2,95 | ≥2.8 | |

| MPA di forza di schiacciamento freddo | Non impregnation | ≥90 | ≥90 | ≥80 | ≥70 |

| Impregnation | ≥110 | ≥110 | ≥100 | ≥90 | |

What are the materials of the ladle slide gate plate?

The materials of ladle slide bricks include high aluminum slide, aluminum carbon slide, aluminum zirconium carbon slide, magnesium carbon and spinel carbon slide, and zirconia slide.

The function of the ladle slide plate

Ladle slide plates are essential components in the steelmaking process. They are used to control the flow of molten steel from the ladle to the tundish during continuous casting. The slide plate is a refractory material designed to withstand high temperatures and mechanical stresses. The ladle slide plate consists of upper and lower slide plates, a sliding mechanism a housing, ecc. The slide plate is operated by a sliding system to allow the molten steel to flow through the ladle and into the tundish. The gate is closed by a reversing process, pushing the upper plate back down onto the lower plate to form a tight seal.

The ladle slide plate precisely controls the flow of molten steel, thereby improving mold filling accuracy and improving the overall quality of the molten steel produced, thereby improving the efficiency of the steelmaking process and reducing overall production costs.

The ladle slide plate is designed to be easily replaced, reducing the downtime required for maintenance and repairs. The ladle slide plate helps prevent accidents and injuries that may occur during the molten steel transfer process.

Gruppo Rongsheng

Gruppo Rongsheng

WeChat

Scansiona il codice QR con wechat