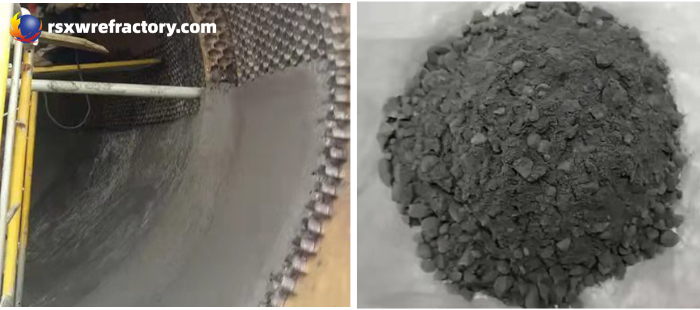

Silicon carbide ramming mass is an amorphous refractory material made of silicon carbide (SiC) as the main raw material, combined with high-purity refractory aggregate, liant, and additives. This material has high thermal conductivity, excellente résistance aux chocs thermiques, erosion resistance, et résistance à l'usure, and is suitable for repair and lining construction of high-temperature industrial equipment, especially for working conditions that require rapid sintering and long-term durability.

Silicon carbide ramming material characteristics

- High refractoriness: temperature resistance can reach above 1600℃, suitable for extremely high temperature environments.

- Excellente résistance aux chocs thermiques: low thermal expansion coefficient, can withstand drastic temperature changes without cracking.

- Chemical erosion resistance: good erosion resistance to acidic and alkaline slag and molten metal (such as aluminum and copper).

- Haute conductivité thermique: SiC’s high thermal conductivity (~120 W/m·K) helps to dissipate heat evenly and improve the thermal efficiency of equipment.

- Forte résistance à l'usure: suitable for high wear areas, such as metallurgical furnace tapping, kiln lining, etc..

- Convenient construction: ramming molding, suitable for repairing and masonry of complex shapes.

Silicon carbide ramming material introduction

| projet | indice | ||

| SC30 | SC50 | ||

| % SiC | ≥30 | ≥50 | |

| Bulk density g/cm3 | ≥2,5 | ≥2,6 | |

| Porosité apparente % | ≤18 | ≤18 | |

| Résistance à la compression normale de température MPA | 110℃×24h | ≥60 | ≥80 |

| 1100℃×3h | ≥100 | ≥120 | |

| Heating permanent line change % 1400℃×3h | ± 0,3 | ± 0,2 | |

| Wear resistance cm3 | ≤6 | ≤4 | |

Application of silicon carbide ramming mass

Metallurgical industry: Repair of linings of electric furnaces, blast furnace tapping channels, ladles, and tundishes.

Nonferrous metal smelting: Linings of aluminum electrolytic cells and copper smelting furnaces.

Industrie chimique: Anti-corrosion layer of gasifiers and incinerators.

Ceramic/glass industry: Wear-resistant layer of furnace bottoms and combustion chambers.

Others: High-temperature pipes, haut fourneau chaud, and other areas that require rapid repair.

Construction method

- Matrix treatment: clean the construction surface, remove impurities, and loose layers.

- Mixing and stirring: Add binder (such as water or resin) in proportion and stir evenly until there is no dry powder.

- Ramming and molding: ramming in layers (each layer ≤ 50mm) to ensure that it is dense and has no pores.

- Curing and baking: after natural curing for 24 heures, bake according to the heating curve (avoid rapid heating).

Groupe Rongsheng

Groupe Rongsheng

WeChat

Scannez le QR Code avec wechat