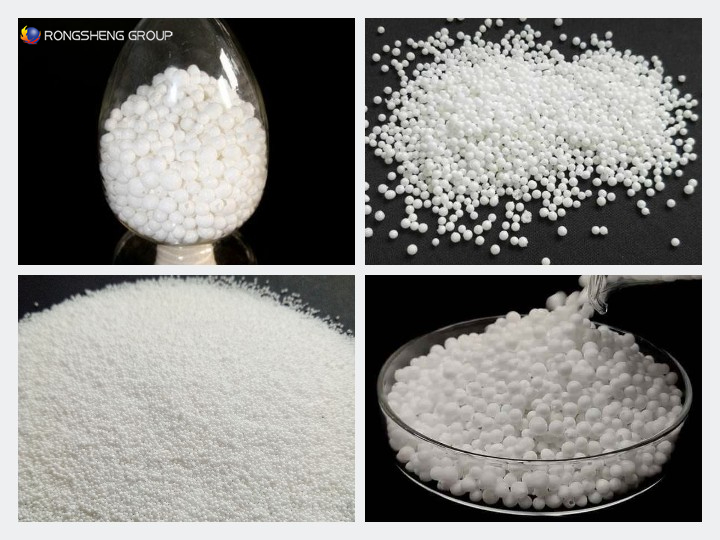

Les boules d'alumine réfractaires à bulles sont un nouveau type de matériau isolant à haute température. Les boules d'alumine réfractaire à bulles sont constituées d'alumine industrielle comme matière première et sont fondues et soufflées dans un four électrique. Les billes creuses d'alumine peuvent être utilisées comme charges d'isolation à haute et ultra haute température.

Que sont les boules d'alumine?

Les billes creuses d'alumine et leurs produits sont des matériaux réfractaires légers et résistants aux températures élevées., économie d'énergie, respectueux de l'environnement, et très stable dans divers environnements. Les billes d'alumine ont des propriétés d'isolation thermique évidentes et une faible conductivité thermique, ce qui peut avoir un bon effet d'isolation thermique, réduire la dissipation thermique, et améliorer l'efficacité thermique, économisant ainsi de l'énergie. L'effet d'économie d'énergie peut atteindre plus de 30%. Il est particulièrement adapté à une utilisation dans des fours à haute température de 1 800 ℃..

Application de billes d'alumine de haute pureté

Les billes d'alumine de haute pureté peuvent être utilisées comme charges d'isolation à haute et ultra haute température, granulats légers pour béton réfractaire haute température, bétons à haute température, briques réfractaires, etc.. Les billes d'alumine de haute pureté sont largement utilisées dans les fours à haute et ultra haute température, fours de navette, Fours de fil molybdène, fours à tige de tungstène, fours à induction, et fours de nitruration tels que les gazogènes dans l'industrie pétrochimique, réacteurs industriels au noir de carbone, et fours à induction dans l'industrie métallurgique. Application, des résultats significatifs ont été obtenus dans la réduction du poids du corps du four, Transformer la structure, matériaux d'économie, Et économiser de l'énergie.

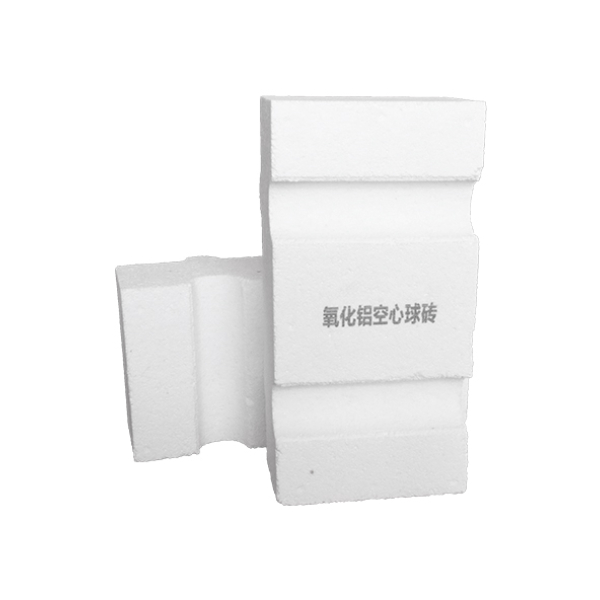

Que sont les briques creuses en alumine?

Briques à billes creuses en alumine Utilisez des billes d'alumine comme corps principal, ils peuvent être transformés en produits de différentes formes. La température maximale de fonctionnement est de 1800°C. La résistance mécanique des produits est élevée, plusieurs fois celui des produits légers ordinaires, et la densité volumique n'est que de la moitié des produits en corindon. Il est largement utilisé dans les fours à haute et ultra haute température..

Avantages des boules d'alumine à bulles réfractaires

- Température de fonctionnement élevée: jusqu'à 1750 diplômes ou plus, bonne stabilité thermique. La ligne de réchauffage a un faible taux de changement et peut être utilisée pendant une période plus longue.

- Optimiser la structure et réduire le poids du four: la densité apparente des briques résistantes aux hautes températures actuellement utilisées est des briques lourdes de 2,6 à 3,0 g/cm, tandis que les briques à billes creuses en alumine ne pèsent que 1,1 à 1,5 g/cm. Pour le même volume de mètre cube, L'utilisation de briques à billes creuses en alumine peut permettre d'économiser 1.1-1.9 tonnes de poids.

- Économiser des matériaux: Pour atteindre la même température de fonctionnement, Si des briques lourdes sont utilisées, le prix est équivalent à celui des briques à billes creuses en alumine, et une quantité considérable de matériaux réfractaires pour la couche isolante sont également nécessaires. Si des briques creuses en alumine sont utilisées, 1.1-1.9 des tonnes de briques lourdes peuvent être économisées par mètre cube, et 80% des matériaux d'isolation réfractaires peuvent être économisés.

- Économie d'énergie: Les boules creux d'alumine ont des propriétés d'isolation thermique évidentes et une faible conductivité thermique, ce qui peut avoir un bon effet d'isolation thermique, réduire la dissipation thermique, et améliorer l'efficacité thermique, économisant ainsi de l'énergie. L'effet d'économie d'énergie peut atteindre plus de 30%.

Groupe Rongsheng

Groupe Rongsheng

WeChat

Scannez le QR Code avec wechat