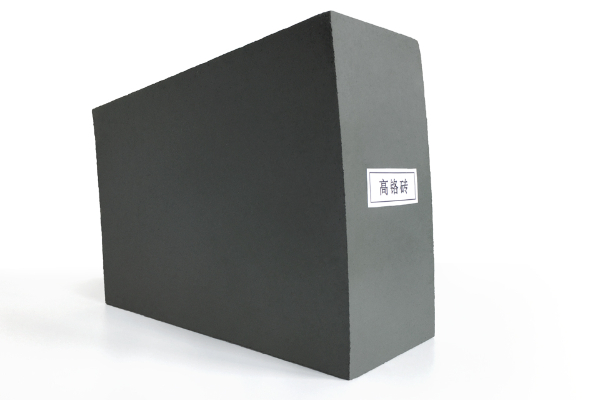

A Russian-based metallurgical company specializing in high-temperature metallurgical production. Due to the extremely high temperatures and corrosive atmospheres involved in their production, customers seek high-quality refractory high-chromium bricks for use in linings and refractory structures of high-temperature equipment.

Russian customer needs

The production environment of Russian customers has very high requirements for refractory materials, especially at high temperatures corrosive gases, and metal erosion. The customer required a high-performance refractory brick that could withstand high temperatures and corrosion. High chromium bricks have excellent high-temperature resistance, Хорошая коррозионная стойкость, износостойкость, and good thermal shock resistance.

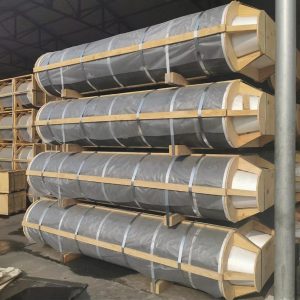

Rongsheng provides high-chrome brick

We provide excellent high-chromium brick according to the customer’s specifications and sizes. During production, we will send some production videos to customers so that Russian customers can control the production progress. В то же время, we provide good after-sales service and usage guidance. Our refractory technical engineers can communicate online with customers about usage details to ensure that customers can put it into use smoothly.

Specific uses for Russian customers to purchase fire bricks

- Blast furnace lining: The lining used in blast furnaces can withstand the impact of high-temperature molten metal and corrosive gases.

- Smelting Furnace Walls: In smelting furnaces, they serve as walls to ensure structural stability at extremely high temperatures.

- Nozzles and deflectors: Used to manufacture high-temperature nozzles and deflectors to withstand high temperatures and wear during the smelting process.

What problems has Rongsheng solved for customers?

- Improved corrosion resistance: High chromium bricks perform well under corrosive gases and metal erosion, greatly extending the service life of the equipment.

- Высокотемпературная стабильность: High chromium bricks maintain structural stability in extremely high-temperature environments, ensuring the normal operation of the production process.

- Improved production efficiency: Due to the stability of the equipment lining, production efficiency is significantly improved, reducing downtime and maintenance costs.

Группа Жуншэн

Группа Жуншэн

Вичат

Сканируйте QR-код с помощью WeChat