How high can the high temperature-resistant calcium silicate board be? In fact, calcium silicate boards can be roughly divided into three categories according to different uses. Different types of calcium silicate boards can withstand different temperatures.

Calcium silicate boards for three purposes

Calcium silicate board for the construction industry

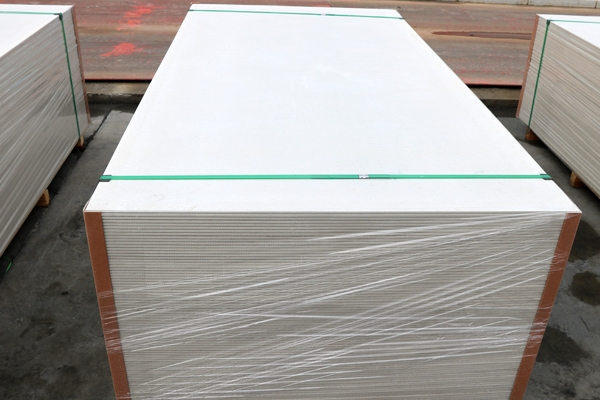

The first type is the common calcium silicate board used for decoration. It is a new type of home decoration building material. This material is moisture-proof and has a long service life. Some of it also has fire-proof properties. It is mainly used in commercial building ceilings, home decoration, and furniture. Some of the inner linings and billboard linings can even be used directly for wall cutting. This kind of calcium silicate board used for decoration can withstand high temperatures of 200℃~400℃.

Industrial microporous calcium silicate boards

The second category is microporous calcium silicate board used in industry, which can also be called calcium silicate board for thermal insulation, asbestos-free microporous calcium silicate board, ecc. Microporous calcium silicate board is a new type of white hard insulation board. This material has the advantages of lightweight, alta resistenza, small thermal conductivity, resistenza alle alte temperature, Resistenza alla corrosione, and easy cutting. It is widely used in equipment pipes, walls, and roofs in the fields of electric power, prodotti petrolchimici, metallurgia, construction, ships, ecc. Thermal insulation and fire and sound insulation. It is one of the best-performing hard block insulation materials at present. Special specifications of microporous calcium silicate board special-shaped parts can be customized according to actual needs. According to the editor’s understanding, this industrial microporous calcium silicate board can withstand High temperatures of 600℃~650℃.

High-temperature resistant calcium silicate board

The third category is high-temperature-resistant calcium silicate boards commonly used in cement plants, power plants, aluminum plants, steel plants, chemical plants, metallurgy industries, glass industries, ceramic industries, and non-ferrous metallurgy industries. High-temperature-resistant calcium silicate boards are the most popular ones. Shengcan provides a 100% asbestos-free high-temperature resistant calcium silicate board, which is a commonly used thermal insulation material for boiler bodies and industrial kilns in electric power, metallurgia, petrochemical, construction, shipbuilding, cement and other industries. According to the usage requirements, the highest temperature of high-temperature resistant calcium silicate board can reach 1100℃.

Characteristics of high-temperature resistant calcium silicate board

- Excellent fire resistance, able to withstand continuous thermal load within temperature limits.

- Bassa conduttività termica. Since the porosity of the product reaches more than 90%, it has unparalleled thermal insulation performance in the entire operating temperature range.

- It is light in weight and has high specific strength. Its specific strength (compressive strength/capacity) is the highest among rigid insulation products.

- Good durability. After long-term use, there will be no pulverization and an obvious decrease in thermal insulation similar to ceramic fiber felt.

- It has strong construction adaptability and can be cut into other shapes with ordinary woodworking tools. It can also be firmly bonded to other components.

- Use and hygiene, and does not contain asbestos, sulfur, chlorine, and other toxic substances. It is non-flammable at high temperatures, smoke-free and odorless, and has a corrosion-inhibiting effect on steel.

Application of high temperature-resistant calcium silicate board

- Cement industry: rotary kiln calciner, preheater tertiary air duct, kiln head cover, cooler.

- Industria metallurgica: heating furnace, soaking furnace, annealing furnace, high-temperature flue, hot air duct.

- Petrochemical industry: heating furnace, ethylene cracking furnace, hydrogenation furnace, aromatics furnace, catalytic cracking furnace.

- Electric power industry: preheating furnace piping.

- Glass industry: furnace bottom and walls.

- Industria ceramica: tunnel kiln, lathe cores, and lathes of tunnel kiln cars.

- Non-ferrous metallurgical industry: electrolyzer.

Gruppo Rongsheng

Gruppo Rongsheng

WeChat

Scansiona il codice QR con wechat