The invention of the ladle shroud nozzle originated from the need for protective pouring of molten steel. Its use has played a good role in preventing secondary oxidation and slag roll-up of molten steel and has played an important role in the development of molten steel continuous casting. The pollution forms of molten steel in the tundish at different stages of continuous casting are almost all directly or indirectly related to the shroud, which has attracted more and more attention from the metallurgical industry.

The use environment of ladle shroud nozzle

Continuous casting functional refractory materials are a type of special materials developed with continuous casting technology in the steel smelting industry. The ladle shroud nozzle, tundish Stopper, a submerged nozzle are three key refractory materials for continuous casting and are also one of the important prerequisites for the normal operation of the continuous casting process. The conditions for using functional refractory materials for continuous casting are harsh. They not only withstand the thermal shock of molten steel but also the dynamic erosion of slag and molten steel. Proto, the functional refractory materials for continuous casting need to have high thermal shock resistance, odolnost proti rozruchu, and erosion resistance to ensure the safety and reliability of the metallurgical process.

The function of the long nozzle in tundish pouring

The ladle shroud nozzle for continuous casting is also called the protective sleeve. It is an important component connecting the ladle and the tundish. It is connected to the lower shroud of the sliding shroud device at the bottom of the ladle, and the lower end extends into the tundish.

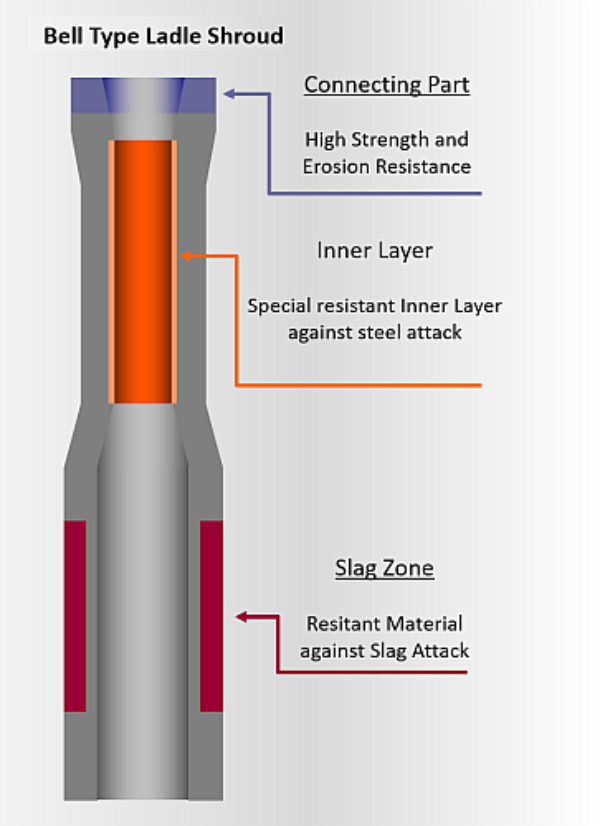

The shroud is an important functional refractory material for maintaining casting and improving steel quality. The length of the shroud is generally 600-1800mm, the pipe diameter is 90-150 mm, and the structure of the ladle shroud nozzle is shown in Figure 2. Its use conditions are harsh and must have the following functions: excellent thermal shock resistance; good mechanical strength; excellent resistance to alternating corrosion of molten steel and slag, high oxidation resistance, and in addition, other suitable properties are required for some special steel grades.

Skupina Rongsheng

Skupina Rongsheng

WeChat

Naskenujte QR kód pomocí wechat