Anti-acid brick is a type of building material specifically designed for use in acid-resistant environments. They are widely used in chemical companies, power plants, Petrochemikálie, and other industrial fields. To ensure the anti-corrosion effect of acid-resistant bricks, this article introduces the precautions for the use of acid-proof bricks.

Choose the right acid-resistant brick material

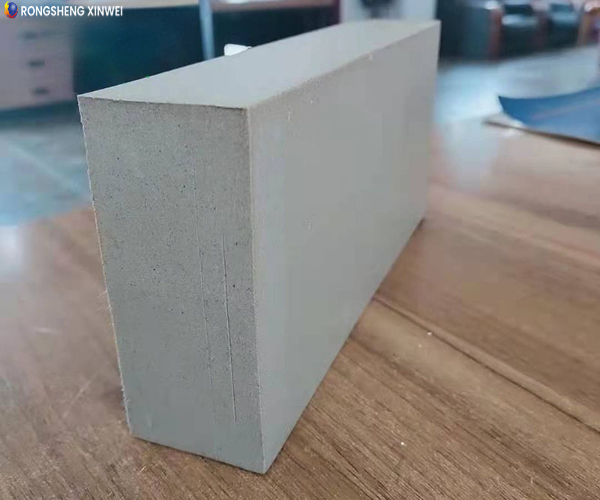

Choose the corresponding acid-resistant brick material according to the type and concentration of acid in the use environment. Generally, acid-resistant bricks can be divided into different types such as sulfuric acid-resistant bricks, hydrochloric anti-acid bricks, and alkali-resistant bricks. The chemical composition and physical properties of each acid-resistant brick are different, so it is very important to choose the right acid-resistant brick material.

Correct construction method of anti-acid brick

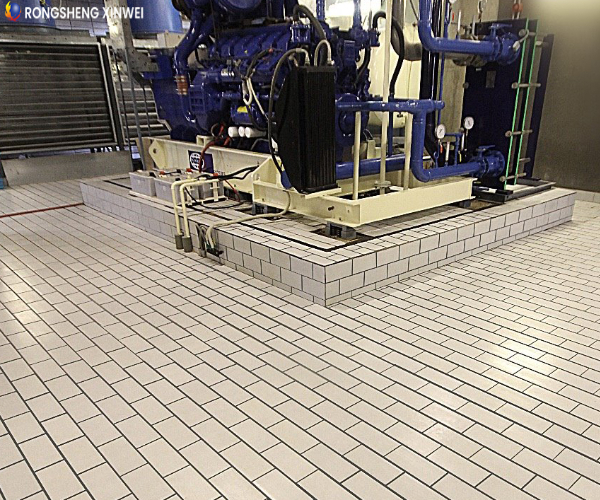

Before laying bricks, the base needs to be cleaned and treated to ensure that it is dust-free, smooth and dry. When laying acid-resistant bricks, special acid-resistant mortar should be used to bond the bricks together, and careful vertical and horizontal corrections should be made to ensure that the brick surface is flat. In addition, during the construction process, care should be taken to avoid mechanical impact and damage to the brick surface.

Correct use of acid-proof bricks

Anti-acid bricks have different grades, and each grade has its own applicable range. Proto, when using acid-resistant bricks, it is necessary to select the appropriate grade and specification according to the specific situation. The types and specifications of acid-resistant bricks required will also be different in different industrial fields and process conditions.

Anti-corrosion coating of anti-acid brick

In order to enhance the corrosion resistance of acid-resistant bricks, anti-corrosion paint can be applied to the brick surface. The selection of coating should be determined according to the specific use environment. Generally, there are two types of anti-corrosion coatings: acidic and alkaline. During the coating construction process, ensure that the coating is uniform and complete to avoid missing coating and damage.

Regular maintenance

Anti-acid bricks should be regularly maintained during use to extend their service life. Keep the surface of acid-resistant bricks clean to avoid any accumulation of impurities and blockage. Regularly check and repair the anti-corrosion coating to avoid acid-resistant bricks losing their corrosion resistance due to problems such as missing coating and falling off. If the brick surface is found to be damaged or broken, it should be repaired and replaced in time.

Use safely

During the construction and use of acid-resistant bricks, relevant safety operating procedures must be strictly followed and necessary personal protective equipment must be equipped, such as wearing protective clothing, gloves, protective masks, atd. At the same time, it is necessary to ensure that the necessary personal protective equipment is equipped, such as wearing protective clothing, gloves, protective masks, atd. At the same time, it is necessary to ensure that the working environment is well-ventilated to avoid harm to workers due to acid gas and steam.

Skupina Rongsheng

Skupina Rongsheng

WeChat

Naskenujte QR kód pomocí wechat