Feuerfeste Materialien werden häufig in industriellen Hochtemperaturbereichen eingesetzt, wie zum Beispiel Metallurgie, Baustoffe, Chemikalien, und Strom. Ihre Leistung wirkt sich direkt auf die Lebensdauer und Produktionseffizienz der Ausrüstung aus. Jedoch, Eine unsachgemäße Lagerung von feuerfestem Material kann dazu führen, dass feuerfeste Materialien feucht werden, oxidiert, geknackt, und es kommt zu Leistungseinbußen, thus affecting construction quality and even increasing costs.

Common problems and cause analysis

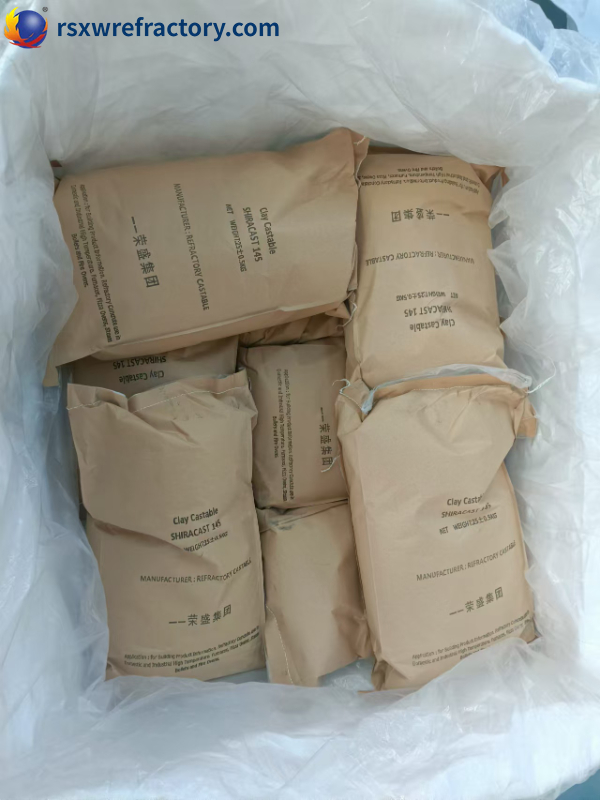

Castables, spray coatings, and refractory clay agglomerate due to moisture

Problem manifestation: Powdered or wet materials such as Gussstücke and refractory mud are prone to moisture and agglomeration during storage, affecting construction performance and even causing inability to use.

Possible causes

The storage environment is humid and the air humidity is too high

The packaging is damaged, causing water vapor to penetrate

Storage time is too long and exceeds the shelf life

Refractory bricks crack or fall off

Problem manifestation: Refractory bricks may crack, fall off, or even break during storage, affecting construction and use.

Possible causes

Repeated changes in wetness and dryness after moisture damage, resulting in structural damage

Improper stacking method, resulting in excessive pressure on refractory bricks

Excessive temperature difference, resulting in thermal stress damage

Moisture absorption and deformation of ceramic fiber products

Ceramic fiber problem manifestations: Ceramic fiber blankets, ceramic fiber boards, and other materials may deteriorate in performance or even deform due to moisture absorption during storage.

Possible reasons

Storage environment humidity is too high, and unsealed packaging

External compression, unreasonable storage method, product moisture absorption, and deformation

Silicon carbide products and magnesia carbon bricks are oxidized

Problem manifestation: Carbon-containing materials such as silicon carbide products and magnesia carbon bricks may be oxidized during storage, affecting their fire resistance.

Possible causes

Long-term exposure to air, reacting with oxygen and moisture

The storage environment humidity is too high, causing the material to gradually oxidize

Refractories react with other chemicals

Problem manifestation: Some refractory materials may undergo chemical changes during storage due to contact with acids, alkalis, oils, and other substances, affecting their performance.

Possible reasons

The storage location is close to chemicals and is contaminated

No effective isolation measures are taken

Rongsheng-Gruppe

Rongsheng-Gruppe

WeChat

Scannen Sie den QR-Code mit Wechat