When the temperature fluctuates, the expansion and contraction of magnesia alumina spinel brick are relatively uniform, the thermal shock stability is good, and the load softening temperature and strength are better than magnesia brick. The ability of magnesia alumina spinel brick to resist alkaline slag and iron oxide slag is stronger than magnesia brick.

Parameter of magnesia alumina spinel brick

| Položka | Index | |||

| MLJ-90 | MLJ-85 | MLJ-80 | MLJ-75 | |

| MGO % | ≥ 90 | ≥85 | ≥ 80 | ≥ 75 |

| Al2Ó3 % | 3~8 | 5~12 | 8~17 | ≥8~12 |

| Zjevná pórovitost % | ≤17 | ≤17 | ≤16 | ≤19 |

| Hromadná hustota G/cm3 | ≥2,95 | ≥2,95 | ≥2.90 | ≥2.85 |

| Pevnost v tlaku za studena MPa | ≥ 45 | ≥ 45 | ≥55 | ≥ 40 |

| 0.2MPa Refractoriness under load ℃ | ≥ 1700 | ≥1650 | ||

| Thermal shock resistance cycle 1100℃water cooling | ≥3 | ≥ 8 | ≥12 | ≥ 8 |

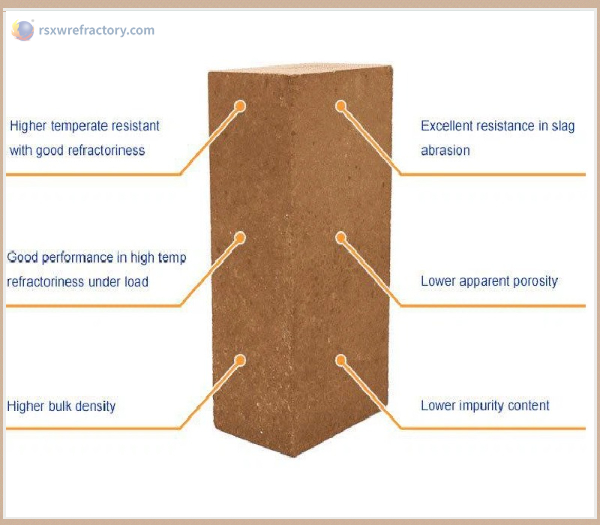

Characteristics of magnesia-aluminum spinel bricks

- Vynikající stabilita tepelných šoků: Magnesia-alumina spinel bricks exhibit excellent thermal shock stability due to their unique internal crystal structure. Whether water-cooled or air-cooled, it can withstand multiple temperature shocks without damage. This characteristic makes it perform well in areas with large temperature fluctuations, such as transition areas of the kiln.

- Increased load softening temperature: Compared with traditional magnesia bricks, the load softening temperature of magnesia-alumina spinel bricks has been significantly improved, reaching 1650 ~ 1700°C. This improvement enables it to maintain structural stability in high-temperature environments and prolongs its service life.

- Strong corrosion resistance: Magnesia-alumina spinel bricks have excellent resistance to alkaline slag and iron oxide slag. This is due to the magnesia-aluminum spinel component inside it, which can protect the periclase particles from the erosion of slag.

- Excellent physical properties: Magnesia-alumina spinel bricks not only have high strength and good structural flexibility but also have low thermal expansion coefficients and low thermal conductivity. These excellent physical properties enable it to maintain a stable shape in high-temperature environments and reduce stress problems caused by thermal expansion.

- Good thermal insulation properties: Magnesia-alumina spinel brick has low thermal conductivity, which means it has good thermal insulation properties. Using this kind of brick in a kiln can play a role in reducing heat loss and improving energy efficiency.

- Excellent wear resistance and erosion resistance: In high-temperature and high-speed airflow environments, magnesia-alumina spinel bricks exhibit excellent wear resistance and erosion resistance. This allows it to maintain a long service life in applications such as cement kilns that need to withstand material erosion and wear.

- Environmental protection and sustainable development: In the manufacturing process of magnesia-alumina spinel bricks, environmentally friendly materials and advanced production processes are used to reduce environmental pollution. At the same time, its high performance and long life also meet the requirements of sustainable development and help reduce the impact of industrial production on the environment.

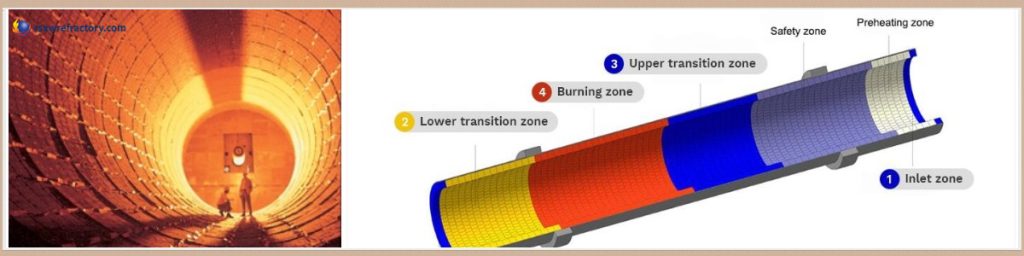

Uses of Magnesia Alumina Spinel Bricks

It can be used as rotary kiln lining (mainly used in the upper and lower transition zones of cement rotary kilns and parts that require high-temperature resistance and thermal shock resistance), electronic furnace roof, ladle lining, open hearth steel storage room, glass furnace heating room checker bricks, atd.

Magnesia-alumina spinel brick size

The standard size of the Rongsheng factory is 230 * 114 * 65mm. If you need other brick sizes and shapes, you can send us the drawings of refractory bricks, and the factory can customize them, including knife-shaped bricks, universal curved bricks, checker bricks, atd. Welcome to contact us.

Skupina Rongsheng

Skupina Rongsheng

WeChat

Naskenujte QR kód pomocí wechat