Arc furnace electrodes refer to a kind of resistant electrode made of petroleum coke and pitch coke as aggregates and coal pitch as a binder. It is made by calcining raw materials, crushing and grinding, batching, kneading, shaping, roasting, impregnation, graphitization, and mechanical processing. High-temperature graphite conductive material.

Working principle of electric arc furnace electrode

Graphite electrodes can conduct electricity and generate electricity to melt scrap iron or other raw materials in blast furnaces to produce steel and other metal products. They are mainly used to make steel. Graphite electrodes are the only material with low resistivity that can withstand thermal gradients within an electric arc furnace. It is mainly used for steelmaking, as well as smelting yellow phosphorus, industrial silicon, abrasives, va hokazo. It is a conductor that releases electric energy in an arc form to heat and melt the charge in the electric furnace.

Classification of graphite electrodes

Graphite electrodes can be divided into three types: ordinary power graphite electrode (RP), high power graphite electrode (HP), and ultra-high power graphite electrode (UHP). According to the different raw materials and physical and chemical indicators of the finished products, graphite electrodes can be divided into three categories, namely ordinary power graphite electrodes, high-power graphite electrodes, and ultra-high power graphite electrodes.

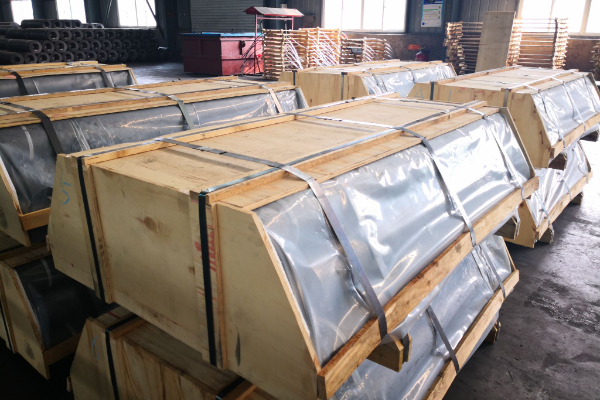

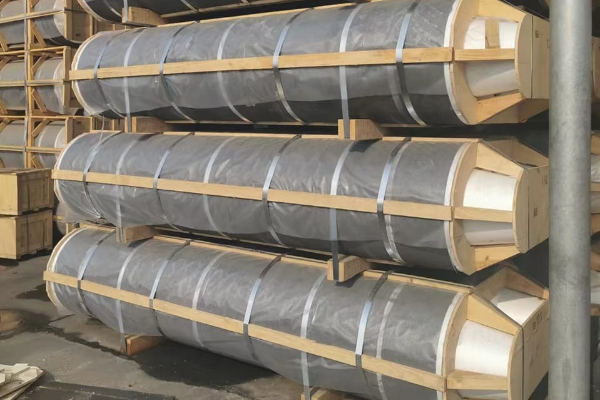

Graphite electrode production process

The production process of graphite electrodes mainly includes raw product manufacturing (crushing, batching, kneading, forming), roasting, impregnation (primary impregnation, secondary impregnation), re-baking, graphitization, mechanical processing, va boshqa jarayonlar. Among them, the main process of roasting has a relatively long production cycle. The production cycle of ordinary power graphite electrode bodies takes about 3 months, while the production cycle of ultra-high power graphite electrodes takes about 5 months.

Rongsheng guruhi

Rongsheng guruhi

WeChat

QR kodini wechat orqali skanerlang