Fused α-β corundum brick is an alumina-based refractory material made by melting and casting high-purity alumina raw materials at temperatures above 2000°C. Due to the different Na2โอ3 เนื้อหา, the composition ratio of α-Na2O3 and aluminum chemicals is different, so fused corundum bricks are specifically divided into three categories: α-Na2โอ3, α-βNa2โอ3, and β-Na2โอ3.

The production process of fused α-β corundum bricks

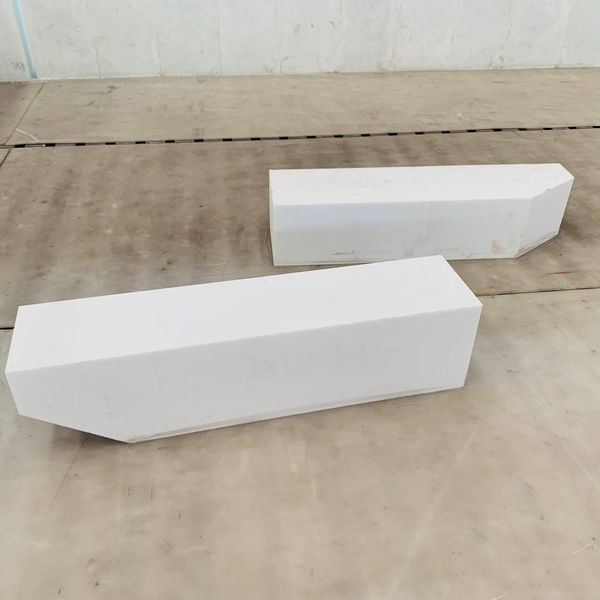

Fused α-β corundum bricks are made of high-purity calcined alumina and a small amount of additives, with an alumina content of >95%. After batching, they are put into a three-phase electric arc furnace, smelted at a high temperature above 2300°C, and then cast into a special mold. , take it out after thermal insulation annealing, and the rough bricks will undergo precise cold processing, pre-assembly, and inspection to become fused corundum bricks that meet customer needs.

Application of fused α-β corundum bricks

Fused α-β corundum brick is a high-grade fused refractory material used in glass furnaces. Due to its excellent performance in resistance to glass erosion, resistance to foaming, and resistance to stones, especially its ability to pollute the glass liquid with almost no pollution, ดังนั้น, it is widely used in glass molding parts such as the clarification section of the glass melting furnace, the working tank, the flow channel, and the feed channel.

Pouring method of fused refractory materials

Electric fused refractory materials are cast from high-temperature liquid material. The liquid material will shrink during the condensation process and produce shrinkage cavities. The shrinkage cavities must be considered during casting, so different bricks have different pouring methods.

As fused AZS bricks, there are usually four manufacturing methods: ordinary casting (RC), tilted casting (TC), non-shrinkage casting VF), and quasi-porous (ENC). อย่างไรก็ตาม, the fused AZS bricks as a whole are only ordinary cast. There are two casting methods: casting (RC) and shrinkage-free casting (VF).

Conventional casting (RC) is a common casting method. The shrinkage cavities in the product exist in the lower part of the casting opening. It is usually used in parts such as the upper structure of glass-melting furnaces where corrosion is relatively slow. อย่างไรก็ตาม, the overall temperature of the parts where the fused α-β corundum bricks are used is much lower than the parts where the fused AZS is used. ดังนั้น, the walls and pavements of the working pool and the forehearth bricks are also made of ordinary cast products without shrinkage holes. Casting (VF) concentrates shrinkage cavities on the sprue during manufacturing. After cooling, the sprue is cut off to produce a product without shrinkage cavities. อย่างไรก็ตาม, a small amount of shrinkage cavities within the standard range are allowed to remain on the cut surface. Castings without shrinkage holes are widely used in the walls and pavements of working pools, feed channels, channels, and other parts.

กลุ่มหรงเฉิง

กลุ่มหรงเฉิง

วีแชท

สแกนรหัส QR ด้วย wechat