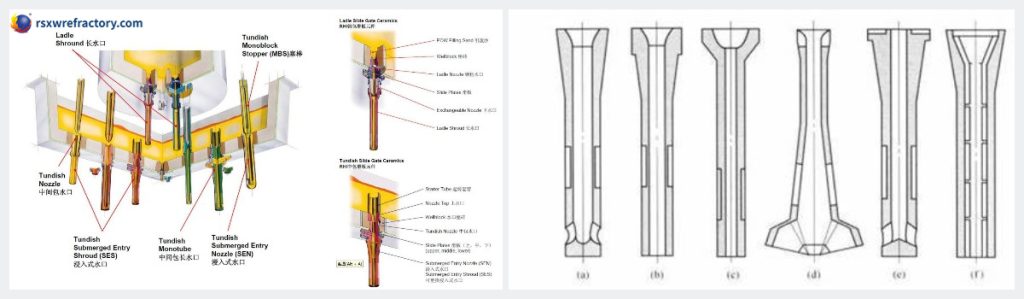

หัวฉีดที่จมอยู่ใต้น้ำสามารถป้องกันเหล็กหลอมเหลวจากการเกิดออกซิเดชันเมื่อไหลเข้าสู่การตกผลึกจาก tundish, กระจายเหล็กหลอมเหลวอย่างเท่าเทียมกัน, และควบคุมสถานะการไหลของเหล็กหลอมเหลวในผลึก, ด้วยความต้านทานตะกรันที่ดี, ต่อต้านการปิดกั้น, อายุการใช้งานที่ยาวนาน, และอัตราการเกิดอุบัติเหตุต่ำ.

พารามิเตอร์ทางเทคนิคของหัวฉีดที่จมอยู่ใต้น้ำ

ตัวชี้วัดทางกายภาพและทางเคมี:

| รายการ | ดัชนี | |||

| JSK55 | JSK50 | JSK45 | JSK40 | |

| อัล2โอ3 % | ≥55 | ≥50 | ≥45 | ≥40 |

| C % | ≥16 | ≥18 | ≥20 | ≥22 |

| MPA ความแข็งแรงของแรงดัดงอ | ≥5.5 | ≥5.5 | ≥5.5 | ≥5 |

| รูพรุนที่ชัดเจน % | ≤19 | ≤19 | ≤19 | ≤19 |

| ความหนาแน่นจำนวนมาก g/cm3 | ≥2.36 | ≥2.32 | ≥2.28 | ≥2.18 |

พื้นที่ตะกรัน:

| รายการ | ดัชนี | |||

| Z75 | Z70 | Z65 | Z55 | |

| zro2 % | ≥75 | ≥70 | ≥65 | ≥55 |

| C % | ≥9 | ≥12 | ≥15 | ≥18 |

| รูพรุนที่ชัดเจน % | ≤21 | ≤21 | ≤21 | ≤22 |

| ความหนาแน่นจำนวนมาก g/cm3 | ≥3.6 | ≥3.5 | ≥3.4 | ≥3.2 |

ฟังก์ชั่นหลักของหัวฉีดที่จมอยู่ใต้น้ำ

(1) ป้องกันการเกิดออกซิเดชันทุติยภูมิและไนเตรทของเหล็กหลอมเหลวและสาดเหล็กหลอม;

(2) ควบคุมสถานะการไหลและความเร็วในการฉีดของเหล็กหลอมเหลว;

(3) ป้องกันการรวมที่ไม่ใช่โลหะในตะกรันป้องกันไม่ให้ถูกดึงเข้าไปในเหล็กหลอมเหลว, ซึ่งมีบทบาทสำคัญในการส่งเสริมการลอยของการรวมในเหล็กหลอมเหลว;

(4) มันมีอิทธิพลอย่างเด็ดขาดต่ออัตราผลตอบแทนของการหล่อด้านข้างและคุณภาพของ Ingot.

กระบวนการผลิตของหัวฉีดที่จมอยู่ใต้น้ำ

กระบวนการผลิตของหัวฉีดที่จมอยู่ใต้น้ำมีดังนี้: วัตถุดิบต่างๆได้รับการนวดเพื่อสร้างผงคอมโพสิตแบบผสมกันอย่างสม่ำเสมอ, ซึ่งถูกกดแบบ isostatically เพื่อสร้างร่างสีเขียวของรูปร่างที่ต้องการ, ซึ่งถูกเผาที่อุณหภูมิสูงเพื่อสร้างผลิตภัณฑ์ที่มีความแข็งแรงบางอย่าง, จากนั้นรูปร่างเป็นขนาดที่ต้องการ. ในที่สุด, หลังจากตรวจสอบ, มันบรรจุและจัดส่งออก.

วัสดุของหัวฉีดที่จมอยู่ใต้น้ำคืออะไร?

วัสดุของหัวฉีดที่จมอยู่ใต้น้ำคือซิลิกาหลอมรวม, กราไฟท์อลูมินาสูง, ควอตซ์, และเซอร์โคเนีย

กลุ่มหรงเฉิง

กลุ่มหรงเฉิง

วีแชท

สแกนรหัส QR ด้วย wechat