พลาสติกทนไฟมีพลาสติกที่ดีพอสมควรและเหมาะสำหรับการสร้างการหล่อ. วัสดุทนไฟพลาสติกที่ถูกสร้างขึ้นใหม่นั้นเกิดจากการผสมมวลรวมวัสดุทนไฟเชิงปริมาณ, พลัง, เพลา, เครื่องผูก, และสารเติมแต่งอื่น ๆ และการบีบให้รูปร่างสีเขียวอิฐ.

วัสดุทนไฟพลาสติกยังคงมีความเป็นพลาสติกที่ดีเมื่อบรรจุอย่างเหมาะสมและเก็บไว้ในช่วงเวลาหนึ่ง. ตามการรวมที่แตกต่างกัน, วัสดุทนไฟพลาสติกสามารถจำแนกเป็นอลูมินาพลาสติกทนไฟได้สูง, ตาม Fireclay, คอรันดัม, ซิลิกา, แมกนีเซีย, โครโมโซม, เซอร์โคเนีย, วัสดุทนไฟพลาสติกคาร์บอรันด์, ฯลฯ. วัสดุทนไฟพลาสติกที่ขึ้นรูปได้เป็นทางออกที่ยอดเยี่ยมเมื่อ เตะทนไฟได้ และ อิฐทนไฟ ซับซ้อนเกินไปหรือยุ่งยากและไม่สามารถใช้งานได้. พลาสติกทนไฟมีความแข็งแรงที่ยอดเยี่ยมและความหนาแน่นสูง, เช่นเดียวกับการเสียดสี, ตะกรัน, และความต้านทานสแควร์, และสามารถใช้ในแอปพลิเคชันที่หลากหลาย. การกระแทกพลาสติกทนไฟก็ทนต่อโลหะหลอมเหลว, ซึ่งทำให้เหมาะสำหรับแอปพลิเคชันเช่นงานหม้อไอน้ำ, เตาหลอม, บุผิว tundish, วัสดุบุผิว, บล็อกเตาเผา, และแพทช์.

ตัวชี้วัดทางกายภาพและทางเคมีของพลาสติกทนไฟ

| รายการ | RSA-45 | RSA-60 | RSA-70 | RSA-75 | RSA-80 | RSA-90 | |

| ความหนาแน่นแห้ง (g / cm3) ≥ | 2.3 | 2.5 | 2.6 | 2.65 | 2.7 | 3 | |

| เคมี (%) | Al2O3 ≥ | 45 | 60 | 70 | 75 | 80 | 90 |

| ZRO2 | - | - | - | - | - | - | |

| โมดูลัสของการแตก(เมปา) | 110℃× 24H ≥ | 5 | 8 | 9 | 9 | 10 | 12 |

| 1500℃× 3H ≥ | 8(1350℃) | 10 (1450℃× 3H) | 12 | 15 | |||

| แรงอัด(เมปา) | 110℃× 24H ≥ | 30 | 40 | 40 | 45 | 45 | 60 |

| 1450℃× 3H ≥ | 60 | 80 | 80 | 85 | 90 | 85 | |

| การเปลี่ยนแปลงมิติเชิงเส้นหลังจากถูกไล่ออก (1500℃× 3H) % ≤ | ± 0.5 | ± 0.5 | ± 0.5 | ± 0.5 | ± 0.5 | ± 0.5 | |

| 1350℃× 3H | 1450℃× 3H | 1450℃× 3H | 1450℃× 3H | ||||

| การหักเหของแสง(℃) ≥ | 1710 | 1740 | 1790 | 1790 | 1790 | 1790 | |

| อุณหภูมิที่ทำงาน (℃) | 1450 | 1450 | 1500 | 1550 | 1600 | 1650 | |

ลักษณะของวัสดุทนไฟเสาหินพลาสติก

- มีความแข็งแรงสูง: วัสดุทนไฟพลาสติกมีความแข็งแรงแรงอัดสูงและความแข็งแรงของการดัดงอ, และสามารถทนต่อแรงกดดันและผลกระทบได้มากขึ้น.

- ประสิทธิภาพที่ทนไฟได้ดี: อุณหภูมิทนไฟของพลาสติกทนไฟสามารถเข้าถึงได้สูงกว่า 1,000 ℃, และสามารถรักษาประสิทธิภาพที่ดีในสภาพแวดล้อมที่อุณหภูมิสูง.

- ความต้านทานการสึกหรอและการกัดกร่อน: พลาสติกเสาหินทนไฟมีการสึกหรอและความต้านทานการกัดกร่อนที่ดี, และสามารถรักษาอายุการใช้งานที่ยาวนานในระหว่างการใช้งาน.

- พลาสติกแข็งแรง: วัสดุทนไฟพลาสติกมีความเป็นพลาสติกที่ดีและสามารถแปรรูปได้อย่างง่ายดายเป็นผลิตภัณฑ์ที่มีรูปร่างและขนาดต่าง ๆ.

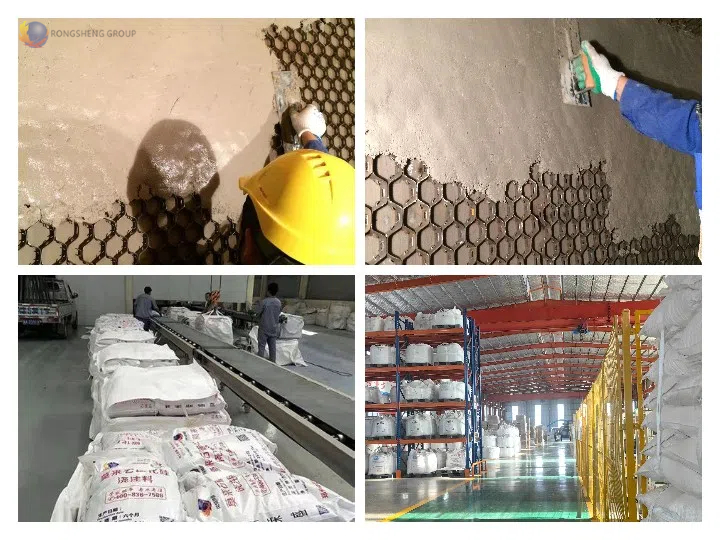

การก่อสร้างพลาสติกทนไฟ

วิธีการก่อสร้างพลาสติกทนไฟ

วัสดุทนไฟเสาหินพลาสติกมีความแข็งแรงพลาสติกและมักจะถูกสร้างขึ้นโดยวิธีการกระแทก. หลังจากการกระแทกที่แข็งแกร่งและการอบอุณหภูมิสูง, มันเป็นโครงสร้างเซรามิก. โครงสร้างขนาดกลางและอุณหภูมิสูงมีความแข็งแรงสูง, ความต้านทานการสึกหรอที่แข็งแกร่ง, และความต้านทานการกระแทกด้วยความร้อนที่ยอดเยี่ยม.

ข้อควรระวังในการก่อสร้างสำหรับวัสดุทนไฟเสาหินพลาสติก

- ระหว่างหรือหลังการก่อสร้าง, การก่ออิฐพลาสติกไม่ได้รับอนุญาตให้สัมผัสกับน้ำ. ในระหว่างการก่อสร้างฤดูหนาว, ควรให้ความสนใจกับการต่อต้านการแช่แข็ง.

- ในช่วงพักก่อสร้าง, ร่างกายที่กระแทกควรถูกตัดเป็นพื้นผิวตรง, นั่นคือ, พื้นผิวพลาสติกกระแทกควรตั้งฉากกับเปลือกเตาเผา. ควรปิดและห่อด้วยฟิล์มพลาสติกเพื่อป้องกันการสูญเสียน้ำ. หากขุดยังคงดำเนินต่อไป, พื้นผิวแห้งควรถูกตัดออกและโกน.

- เมื่อสร้าง castables ที่จุดติดต่อด้วยพลาสติก, การกันน้ำพลาสติกควรทำได้ดี.

กลุ่มหรงเฉิง

กลุ่มหรงเฉิง

วีแชท

สแกนรหัส QR ด้วย wechat