Beryllium oxide (Beo) ceramic plate belongs to the cubic crystal system, with a density of 3.03g/cm3 and a melting point of 2570 ℃. It has high thermal conductivity and thermal conductivity λ It is 200-250W/(m · K), and has good thermal shock resistance. The dielectric constant is 6-7 (0.1MHz), and the dielectric loss tangent is about 4 × 10-4 (0.1GHz), it can be used for a long time under 1800 ℃ vacuum, 2000 ℃ inert atmosphere, e 1800 ℃ oxidation atmosphere.

Description of Beryllium Oxide Ceramic

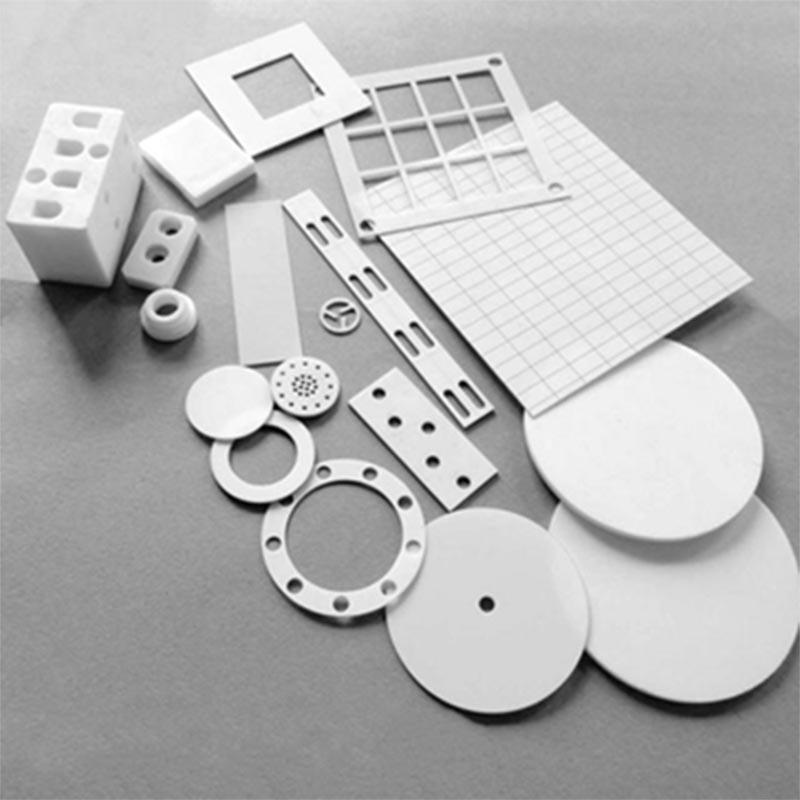

Beryllium oxide ceramic is an advanced ceramic with beryllium oxide (Beo) as the main component. It is characterized by high thermal conductivity, high melting point, alta resistência, high insulation, high chemical and thermal stability, low dielectric constant, low dielectric loss, and good process adaptability. It is a structural ceramic material with excellent performance and is widely used in special metallurgy, aerospace, vacuum electronics, nuclear technology, microelectronics,s and optoelectronics, Especially in high-power semiconductor devices, high-power integrated circuits, high-power microwave vacuum devices, and nuclear reactors, it has been the mainstream ceramic materials for preparing high thermal conductivity components.

Óxido de berílio (Beo) Ceramic Plate applications

Due to its excellent thermal, electrical, nuclear, and mechanical properties, beryllium oxide ceramics can be used as carrier parts and assemblies in the aerospace field, as a neutron retarder and radiation protection material in atomic reactors in the nuclear industry, as a high-performance, high-power microwave package, as well as a wide band high-power electric vacuum device, and as a crucible for melting rare metals and precious metals, such as uranium and plutonium, It can also be used as refractory material for supporting rods of heating elements, etc., and has an excellent application in various fields.

Technical Parameter of Beryllium Oxide Ceramic

| Item | Test Condition | Unit | Índice |

| Bulk Density | g/cm3 | ≥2.85 | |

| Beryllium oxide content | % | ≥99 | |

| Airtightness | Pass | ||

| Liquid permeability | Pass | ||

| Flexural strength | MPA | ≥170 | |

| Thermal shock resistance | Pass | ||

| Coefficient of linear expansion | 20℃-500℃ | × 10-6 /℃ | 7-8.5 |

| Condutividade térmica | 25℃ | W/(m·k) | ≥250 |

| Partial constant | 100℃ | W/(m·k) | ≥190 |

| Tangent value of dielectric loss angle | 1MHz 20℃ | 6.5-7.5 | |

| Volume resistivity | 10GHz 20℃ | 6.5-7.5 | |

| Breakdown strength | 1MHz 20℃ | × 10-4 | ≤4 |

| Chemical stability | 10GHz 20℃ | × 10-4 | ≤8 |

| N o | Product | Aplicativo |

| 1 | 99 Beryllium oxide ceramic substrate | Solid-state electronics, various high-power devices, optical communication |

| 2 | 99 Beryllium oxide ceramic metallized substrate | Solid state electronics, various high-power devices, optical communication |

| 3 | 99 Beryllium oxide ceramic polishing substrate | Solid-state electronics, various high-power devices, optical communication |

| 4 | 97 Beryllium oxide ceramic substrate | Solid-state electronics, various high-power devices, optical communication |

| 5 | 99 Beryllium oxide ceramic pole | High-power traveling wave tube |

| 6 | 99 Beryllium oxide ceramic tile | High-power electronic device |

| 7 | 99 Beryllium oxide ceramic column | High power electronic device |

| 8 | 99 Beryllium oxide ceramic cylinder | Vacuum device |

| 9 | 99 Beryllium oxide ceramic crucible | Melting |

| 10 | 99.5 Beryllium oxide ceramic shaped parts | Nuclear, high power period, vacuum device, microwave |

Grupo Rong Sheng

Grupo Rong Sheng

WeChat

Digitalize o código QR com wechat