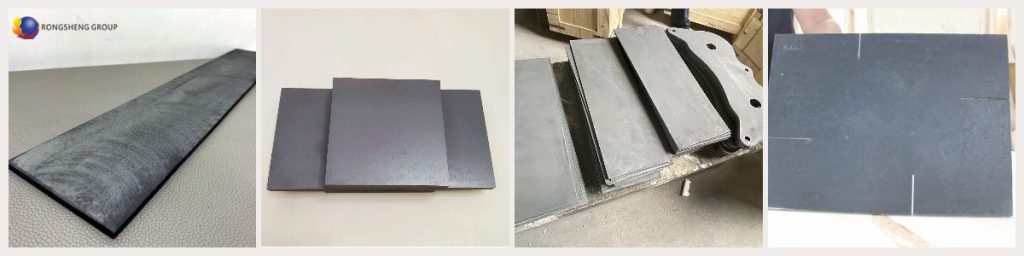

Silicon carbide plate is made of high-quality karbid křemíku as the main raw material and special chemical raw materials as binders. They are made in different sizes. Silicon carbide plates are a form of processing silicon carbide into a flat shape. It combines the inherent properties of silicon carbide. Vlastnosti, such as extremely high hardness, thermal stability, tepelná vodivost, and resistance to wear, corrosion, and thermal shock, make it an ideal material for various applications. Due to its robustness and durability, silicon carbide plates withstand high temperatures and mechanical stress It also has its unique application value in environments with corrosive substances.

Silicon carbide raw material introduction

Silicon carbide (Sic) is a highly durable and strong material known for its hardness and high thermal conductivity. This hardness makes silicon carbide a useful material for abrasives, cutting tools, and components subject to high wear. Due to the unique properties of silicon carbide, it is widely used in industrial, electronic, and energy fields, especially power electronics and high-voltage and high-temperature equipment. Silicon carbide is one of the raw materials used to make silicon carbide plates and cihly křemíku karbidu.

Features of silicon carbide plate

- Vysokoteplotní odpor

- Excellent hardness and wear resistance

- Excellent thermal conductivity and shock resistance

- Not easy to oxidize

- Excellent hardness and wear resistance

- Low thermal expansion

- Lehký

The manufacturing process of silicon carbide plate

Powder preparation. The preparation of high-purity silicon carbide powder and grinding of the powder mix to achieve the required particle size and uniformity are critical to the consistency and quality of the plates.

Forming. The prepared powder is made into silicon carbide sheets by dry pressing, isostatic pressing, or slip molding.

Sintering. To sinter the green body, different sintering methods can be used, including pressureless sintering, hot pressing, and reaction bonding.

Post-processing. After sintering, the boards may need to be machined to achieve precise dimensions or surface finish. Silicon carbide is very hard, so it is often cut and shaped using diamond tools. Depending on the application, the boards may also be surface treated to enhance properties such as corrosion resistance or to apply coatings.

Application of silicon carbide plates

Silicon carbide plates can be used as high-temperature indirect heating materials in the non-ferrous metal smelting industry, such as vertical tank distillation furnaces, distillation furnace trays, aluminum electrolytic cells, copper melting furnace linings, arc plates for zinc powder furnaces, thermocouple protection tubes, atd.; used to make advanced silicon carbide ceramic materials such as wear-resistant, corrosion-resistant, and high-temperature resistant; and can also be used to make rocket nozzles, gas turbine blades, atd.

Skupina Rongsheng

Skupina Rongsheng

WeChat

Naskenujte QR kód pomocí wechat