Blast fırın şimdi ana eritme ekipmanı, büyük üretim hacminin özellikleri ile, vesaire. Refrakter tuğla astar, yüksek fırınlarda vazgeçilmez bir rol oynar, but in the production process, the refractory brick lining of the furnace wall is gradually eroded by various factors. Öyleyse, in order to extend the service life of the blast furnace, it is necessary to reasonably select refractory brick lining.

Selection of refractory lining for blast furnace

1) Furnace throat. Mainly bear the impact and wear of the charge; generally, steel bricks or water-cooled steel bricks are used.

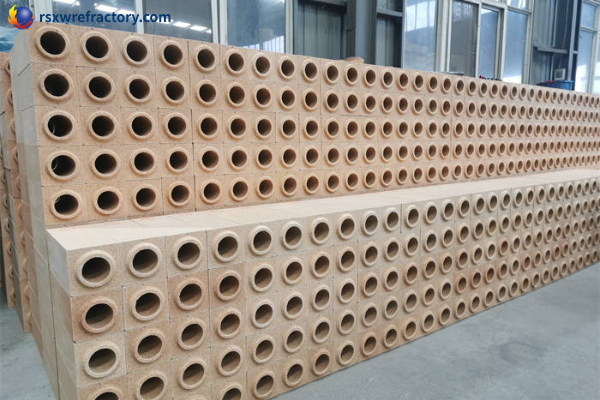

(2) Upper part of the furnace. This part is the area where the carbon deposition reaction 2CO2-CO + C is prone to occur, and the erosion of alkali metals and zinc vapor also occurs in this area. Ek olarak, the scouring and wear of the descending charge and the ascending gas flow, so refractory materials with good chemical corrosion resistance and wear resistance should be selected. The most suitable ones are high-density m-soil bricks, high-density third-class high-alumina bricks or clay bricks impregnated with phosphoric acid. When thin-walled structures are used in modern large blast furnaces, 1 ile 3 sections of reverse cooling walls are often used to replace brick linings.

(3) The middle and lower parts of the furnace body and the furnace waist. The main mechanisms of damage are thermal shock spalling, high-temperature gas scouring, alkali metals, zinc and carbon deposition, and chemical erosion of primary slag. Brick linings should use refractory materials that are resistant to thermal shock, primary slag erosion, and scouring. Şu anda, large blast furnaces at home and abroad The furnace use silicon carbide bricks (silicon nitride bonded, self-bonded, and sialon bonded) with good performance but high price to ensure a service life of more than 8 yıllar. Practice has shown that even the best refractory materials will be eroded and can only be stable when they reach equilibrium (about half of the original thickness), which takes about 3 yıllar. In fact, using fired aluminum carbon bricks with good performance (much cheaper) can also achieve this goal. Öyleyse, aluminum carbon bricks can be used in blast furnaces of 1000 m3 and below.

(4) Bosh. The main reason for damage is the erosion of high-temperature coal gas and slag iron. The heat flow intensity of this part is very large, and any refractory material cannot resist it for a long time. The refractory life of this part is The life span is not long (1-2 months at most, 2-3 weeks at least), and refractory materials with high refractoriness, Yük altında yüksek refrakterlik, and high bulk density are generally selected, örneğin yüksek alümina tuğlalar, aluminum-carbon bricks, vesaire.

(5) Hearth tuyere area. This area is the only area in the blast furnace where an oxidation reaction takes place. The high temperature generated can reach 1900-2400℃. The brick lining is damaged by thermal stress caused by high temperature, as well as high temperature gas erosion, slag iron erosion, alkali metal erosion, and circulating coke erosion. Modern blast furnaces all use composite bricks to build the hearth tuyere area. The materials are high alumina, corundum mullite, kahverengi korundum, and silicon carbide combined with silicon nitride, vesaire. There are also hot-pressed carbon blocks.

(6) The lower part of the hearth and the bottom of the furnace.e In areas where blast furnace lining erosion is serious, the degree of erosion has always been the basis for determining the life of a generation of blast furnaces. Early furnace bottoms were mostly made of single ceramic refractory materials because they had no cooling. Öyleyse, thermal stress caused cracks in the masonry, and molten iron penetrated the cracks and caused the bottom bricks to float, which was the main reason for the damage. Now, good furnace bottom structures (ceramic cups, staggered masonry, vesaire.) and cooling, as well as the use of high-quality brown corundum, gray corundum brick, and carbon microporous and hot-pressed bricks have greatly extended the life of blast furnace bottoms. Fakat, the penetration and dissolution of carbon bricks by molten iron, the chemical erosion of carbon bricks by alkali metals, the damage of carbon bricks by thermal stress, and the oxidation of carbon bricks by CO2 and H2O are still important factors threatening the life of the furnace bottom and hearth.

The production conditions of blast furnaces in different parts are different. Öyleyse, different areas need to purchase different refrakter malzemeler and use them accordingly to avoid unnecessary troubles caused by problems such as refractory materials not meeting the requirements.

Rongsheng Grubu

Rongsheng Grubu

WeChat

QR Kodunu wechat ile tarayın