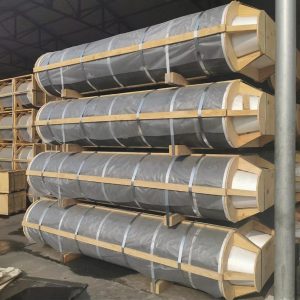

Egyptian Ceramics Industry Customers is committed to providing a wide range of ceramic products, including ceramic tiles, decorative ceramics, and industrial ceramics. Adhering to the persistent pursuit of quality, the company has been pursuing excellence and innovation to meet the market’s demand for high-quality ceramic products. This time we have our first cooperation on cordierite mullite slabs. Here are some details.

Egyptian cordierite mullite slabs customers demand

Customers are faced with the need for fire-resistant boards with strong fire resistance during the production process. During high-temperature firing processes, the setters need to be able to reliably withstand extreme temperatures and thermal shock. Customers urgently need a high-performance setter material to improve the firing quality and production efficiency of their products.

Introduction to setting plates for the ceramic industry

What is a setter? The setter is a tool used in ceramic kilns to carry and transport the fired ceramic bodies. Corundum-mullite set-up board uses high-purity corundum and mullite as the main raw materials. The multi-phase set-up plate fired at high temperatures has excellent properties of both and is not prone to chemical reactions with the set-up products. It can be used repeatedly under a high-temperature intensity of 1450 degrees and is especially suitable for sintered magnetic cores, ceramic capacitors, and insulating ceramics.

Characteristics of cordierite mullite burning boards

The set-up plate has excellent characteristics such as high working temperature, good thermal shock stability, small expansion coefficient, high flexural strength, excellent high-temperature load-bearing softening performance, and long overall service life.

Rongsheng Grubu

Rongsheng Grubu

WeChat

QR Kodunu wechat ile tarayın