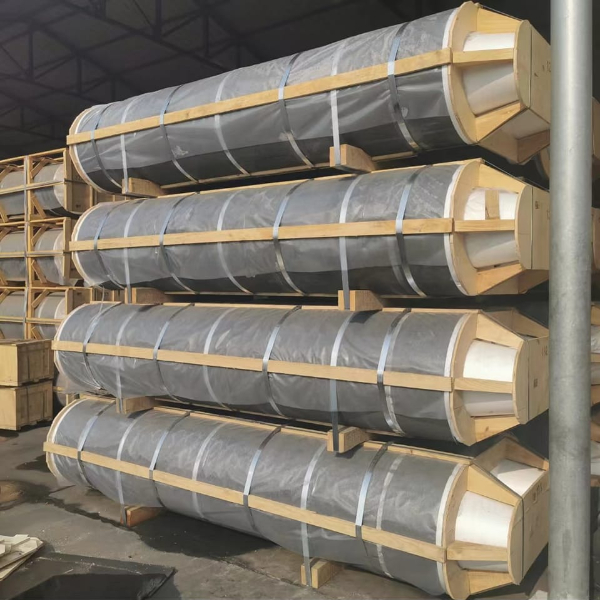

Rongsheng Refractory Materials Company is a Chinese refractory material supplier with 20 years of production experience. It is committed to providing high-quality refractory bricks, insulation materials, and continuous casting products to the industrial field to meet the diverse needs of customers. In September, we successfully cooperated with a steel company in Venezuela and exported a batch of high-quality graphite electrodes.

Venezuela customer introduction

Venezuelan steel companies, as important participants in the country’s steel industry, have been seeking solutions to improve the production efficiency of electric arc furnaces to cope with the pressure of market competition. In the process of capacity expansion, customers urgently need an efficient and stable electrode material to ensure stable operation and higher output of electric arc furnaces.

Get in touch with us

The engineering team of Rongsheng Refractory Materials Company actively intervened and gained an in-depth understanding of the customer’s production process and the characteristics of the electric arc furnace. Through precise material analysis and experimental verification, they recommend a series of high-quality graphite electrodes to customers to ensure that they can maintain excellent performance in high-temperature and high-pressure environments.

Rongsheng graphite electrode features

- High conductivity: Rongsheng’s graphite electrodes are made of a high-quality graphite material, which has excellent conductivity, effectively reduces resistance loss, and improves power utilization.

- Oxidation resistance: The special surface treatment process makes the graphite electrode have excellent oxidation resistance, which can maintain stability in high-temperature environments and extend its service life.

- Accurate dimensions: Rongsheng’s graphite electrodes undergo strict manufacturing processes to ensure precise dimensions and a perfect match with the electrode system of the electric arc furnace.

What changes have occurred in Venezuelan customer production after cooperation?

- Improved production efficiency: New graphite electrodes have greatly improved the working efficiency of electric arc furnaces, significantly increasing the speed of steel production.

- Energy Saving and Emission Reduction: The excellent conductive properties of graphite electrodes effectively reduce electrical energy loss, reducing energy consumption and environmental emissions.

- Improved product quality: The stability and durability of graphite electrodes ensure consistency during continuous production, significantly improving the quality of the final product.

- Cost reduction: Rongsheng Refractory Materials’ graphite electrodes are not only reasonably priced, but their long life characteristics reduce customers’ costs in maintenance and replacement.

Rongsheng Group

Rongsheng Group

WeChat

Matawai te Waehere QR me te wechat