Description of High Temperature Resistance Crucible

Crucibles mainly include silicon carbide crucible and graphite crucible, which are mainly made of flake graphite and silicon carbide. They have the characteristics of good thermal conductivity, high density, corrosion resistance, less slag adhesion, high mechanical strength, oxidation resistance, thermal shock resistance, etc. they do not react with molten metals in the smelting process, and are not easy to leak and adhere. They are widely used in the smelting of alloy tool steel and the smelting of non-ferrous metals such as copper, aluminum and their alloys.

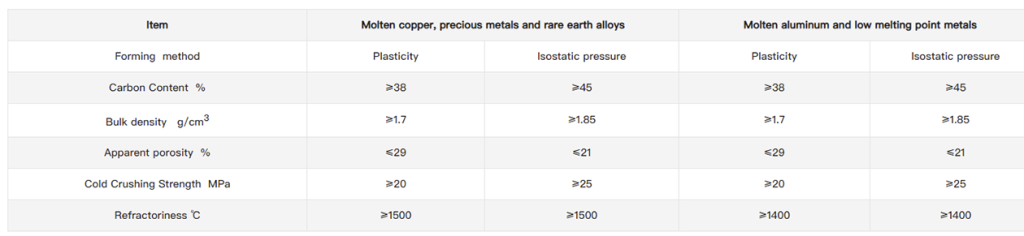

Technical Parameter of High Temperature Resistance Crucible

Rongsheng Group

Rongsheng Group

WeChat

Matawai te Waehere QR me te wechat