The Chilean customer is an industrial equipment manufacturing company that mainly serves the mining and metallurgical industries. Their products need to face high temperatures and complex thermal environments. Saat ini, the customer is looking for a material that can withstand high temperatures and has thermal insulation properties for the lining and thermal insulation of high-temperature equipment. Finally, the customer ordered our refractory wool.

Contact us and get a quote

The Chilean customer contacted us through our website. The business manager of Rongsheng Refractory Materials Company immediately contacted the customer to understand the needs of this Chilean customer. After a period of communication, we understood the customer’s needs and sent the customer a quotation for refractory wool.

Recommend suitable refractory wool to customers

Based on customer needs, we recommend ceramic fiber blankets to them. This material is made of high-purity alumina and silica, has excellent refractory and heat insulation properties, and is widely used in high-temperature industries such as metallurgy, ceramics, and glass.

Features of ceramic fiber blankets

High-temperature resistance: The operating temperature of ceramic fiber blankets can be as high as 1200°C, which fully meets customer needs.

Low thermal conductivity: Maintain excellent insulation effect in high-temperature environments, greatly reduce heat loss, and improve energy utilization efficiency.

Lightweight: Compared with traditional refractory bricks or other insulation materials, ceramic fiber blankets are lighter and help reduce the burden on equipment.

Convenient construction: Good softness, can be cut and fixed according to the shape of the equipment, saving installation time.

Environmentally friendly and non-toxic: The production of materials meets environmental protection requirements, no harmful substances are released, and fully meets Chile’s environmental protection standards.

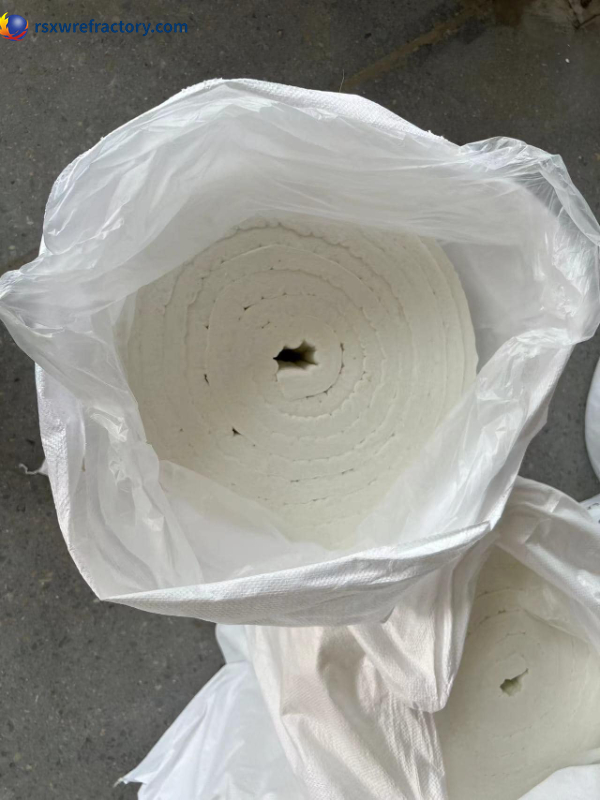

Ceramic fiber blanket delivery

Before signing the contract, we sent free samples to the customer for testing. The customer conducted multiple tests on the samples in the laboratory, including performance evaluations in terms of high-temperature resistance, thermal conductivity, and tensile strength. The test results fully met their expectations, especially the material’s efficient thermal insulation performance and softness and ease of use, which were unanimously recognized by the customer’s technical team.

After the test results were confirmed, the customer placed the first order. Our refractory material factory began production to ensure that customized ceramic fiber blankets were provided according to customer requirements, including specific sizes and packaging designs to suit their construction needs.

To ensure that the goods arrived on time, we chose a reliable sea transportation method and prepared all relevant documents according to Chile’s import requirements. Throughout the transportation process, we maintained real-time communication with the customer to ensure that the goods were delivered safely and efficiently.

Chile customer feedback

After the goods arrived, the customer immediately applied the ceramic fiber blankets to the insulation renovation project of their industrial equipment. After a period of use, customer feedback is as follows:

- The material’s high-temperature resistance and thermal insulation effect are remarkable, and the thermal efficiency of the equipment has been increased by more than 20%.

- The simplicity of construction has been highly praised by the construction team, saving installation time and costs.

- The environmental performance of the ceramic fiber blanket fully complies with relevant Chilean regulations, and the customer is very satisfied with it.

Grup Rongsheng

Grup Rongsheng

Wechat wechat

Pindai Kode QR dengan WeChat