As an important industrial country in Central Asia, Uzbekistan has seen a continuous increase in demand for refractory materials for high-temperature kilns in recent years. The client in this case is a well-known local cement production company that mainly operates cement kilns and tunnel kilns and requires a large number of high-quality refractory bricks in production. After comparing and investigating multiple suppliers, they finally chose the alumina brick we provided.

Uzbekistan customers’ demand for aluminum bricks

- Aluminum content requirement: The Al₂O₃ content of high-aluminum bricks needs to reach more than 75% to meet the high-temperature requirements of the kiln.

- Compressive strength and thermal shock resistance: The brick body needs to be able to withstand mechanical pressure in a high-temperature environment and maintain stability during temperature fluctuations.

- Transportation and delivery time: Due to the tight project schedule, the customer hopes to complete production and delivery as soon as possible.

Initial communication and sample testing

Through online emails and phone calls, we learned about the customer’s needs in detail and recommended several high-alumina brick models suitable for high-temperature parts of cement kilns. The customer selected a standard high-alumina brick with an aluminum content of 75% for testing. We completed sample production in the shortest possible time and sent the samples to Uzbekistan through logistics.

High alumina brick test and feedback

After receiving the samples, the customer tested the high-alumina bricks in the laboratory environment and in actual kiln applications. The experimental results showed that our high-alumina bricks exhibited excellent compressive strength and corrosion resistance at high temperatures, especially its good thermal shock resistance, which was highly recognized by the customer. The customer immediately confirmed the intention to purchase in large quantities.

Confirm the order and arrange production

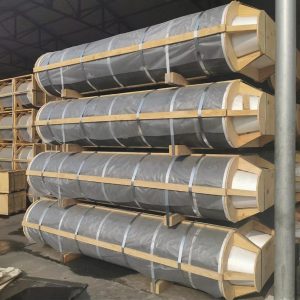

After both parties confirm the contract details, we will start production immediately. In order to ensure product quality, we strictly control every process, including raw material selection, ingredients, pressing, and high-temperature sintering. After production is completed, we also arrange a quality inspection to ensure that each brick meets customer requirements.

Rongsheng-Gruppe

Rongsheng-Gruppe

WeChat

Scannen Sie den QR-Code mit Wechat