A leading South African metallurgical company focused on the production of high-quality alloy products. Since its smelting process requires it to withstand extreme temperatures and corrosive atmospheres, the customer sought a high-performance refractory material. Our magnesia chrome refractory bricks are their first choice due to their excellent corrosion resistance and high-temperature properties.

The usage environment of refractory bricks required by customers

The internal environment of the South African customer’s smelting furnace is extremely harsh, involving high temperatures, chemical corrosion, and waste gases generated during the metallurgical process. Traditional refractory materials are difficult to cope with such extreme conditions, and customers need a refractory material that can perform well in this harsh environment.

Rongsheng refractory solutions

By analyzing the usage environment of refractory materials for metallurgical customers in South Africa, we provide customers with magnesia-chrome bricks, a refractory material composed of high-purity magnesium oxide and chromium oxide. This material has excellent corrosion resistance and high-temperature stability, making it ideal for lining metallurgical furnaces.

Use of magnesia chrome refractory bricks by South African customers

- Chrome alloy production furnace: Magnesia-chromium bricks are used for lining chromium alloy production furnaces that can withstand metal melting and exhaust gas corrosion under high temperatures and pressures.

- High-temperature melting process: Used to process metal alloys at high temperatures to ensure that the interior of the furnace can withstand high temperatures and corrosion.

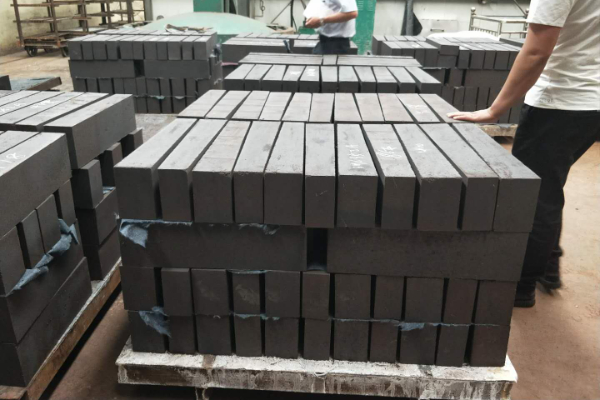

Magnesia chrome refractory brick delivery

Rongsheng guruhi

Rongsheng guruhi

WeChat

QR kodini wechat orqali skanerlang