Honeycomb ceramic regenerators can reduce the heat loss of exhaust gas, improve combustion conditions, improve furnace heat exchange conditions, and reduce exhaust gas emissions from thermal equipment and harmful gas emissions.

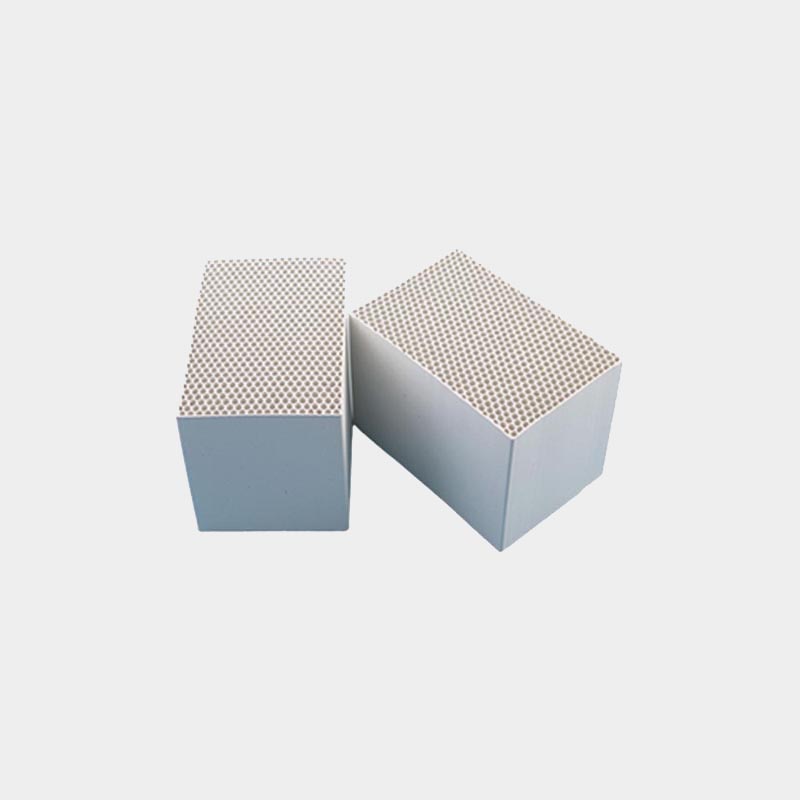

Honeycomb ceramic regenerator description

Honeycomb ceramics are composed of numerous equal holes in various shapes. The current maximum number of holes has reached 20 to 40 per square centimeter, the density is 4 to 6 grams per cubic centimeter, and the water absorption rate is up to 20%. Due to the characteristics of porous thin walls, the geometric surface area of the carrier is greatly increased and the thermal shock resistance is improved. The mesh holes of the products currently produced are mainly triangular and square. The triangular ones have much better bearing capacity than the square ones and have more holes. This is especially important as a catalytic carrier.

With the increase in the number of holes per unit area and the decrease in the thickness of the carrier pore wall, the thermal shock resistance of the ceramic carrier is improved, and the temperature of thermal shock damage is also increased. Prin urmare, honeycomb ceramics must reduce the expansion coefficient and increase the number of holes per unit area.

Technical parameter of good quality honeycomb ceramic

| Property | Material | |||

| Corundum Mullite | Mullite | Cordierite mullite | Cordierite | |

| Compressive strength MPa | C-axis direction≥20 A (B) axis direction≥4 | C-axis direction≥20 A (B) axis direction≥4 | C-axis direction≥20 A (B) axis direction≥4 | C-axis direction≥20 A (B) axis direction≥4 |

| Apparent density g/cm3 | >0.9 | 0.6~1.1 | 0.5~0.9 | 0.4~0.8 |

| Coefficient of thermal expansion 1/℃ RT~800℃ | ≤6×10-6 | ≤5.5×10-6 | ≤3×10-6 | ≤2.5×10-6 |

| Thermal shock resistance temperature ℃ | ≥300 | ≥300 | ≥400 | ≥500 |

| Refractoriness under load ℃ 0.1MPa | ≥1500 | ≥1450 | ≥1350 | ≥1250 |

| Specific heat capacity J/(kg·K) | ≥800 | ≥800 | ≥750 | ≥750 |

| mărimea:100×100×100、100×150×150、150×150×150、150×150×300(mm); Hole:25×25、40×40、43×43、50×50、60×60; Hole type: square, rectangle, regular hexagon, circle, triangle | ||||

Uses of honeycomb ceramics

- Catalyst carrier: When honeycomb ceramics are used as catalyst carriers, they are mainly used in automobile exhaust purification, boiler exhaust denitrification (NOx), industrial exhaust deodorization, and removal of toxic and harmful gases. The honeycomb ceramic catalyst carrier used for automobile exhaust purification is mainly a cordierite honeycomb ceramic carrier coated with γ-Al2O3.

- Refractory kiln: The mass of an extruded honeycomb ceramic kiln is 60%-75% lighter than that of the traditional kiln, and the heat transfer is rapid, which can achieve rapid firing. When using it to pad ferrite or other electronic ceramics, it is beneficial to improve the performance of the product.

- Wall flow filter: The porous thin-walled honeycomb ceramics can filter and purify carbon particles in diesel engine gas exhaust (about 500°C).

Grupul Rongsheng

Grupul Rongsheng

WeChat

Scanați codul QR cu wechat