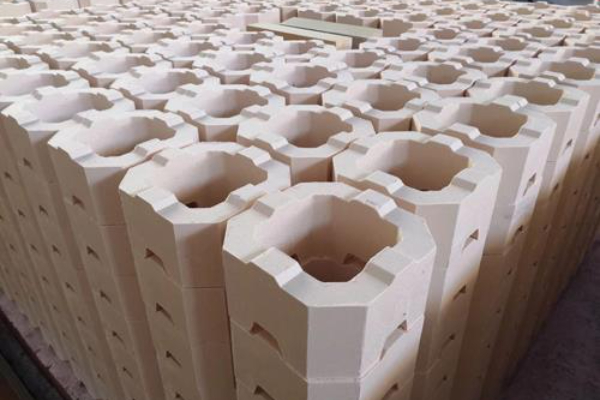

Zircon mullite bricks are a high-temperature refractory material whose main components are zirconium oxide (ZrO2) and silicon dioxide (SiO2). Its unique crystal structure gives it excellent high-temperature stability and wear resistance, making it an ideal refractory material choice, especially in high-temperature industrial environments.

Spanish customer introduction

Our company signed a zirconium mullite brick supply contract with a leading Spanish heavy metallurgical company. The company, located in Barcelona, Sepanyol, has many years of experience in high-temperature smelting and has an excellent reputation in ferroalloy production. They are known in the industry for their rigorous craftsmanship and high-quality products, so they need high-performance refractory materials to ensure the stability and efficiency of production.

The purpose of customers purchasing zirconium mullite bricks

The Spanish customer purchased zirconium mullite bricks mainly for repairing high-temperature kilns on its production line. Specifically, zirconium mullite bricks are used in the smelting hearth area inside the kiln. The furnace is one of the most important components in the entire smelting process, responsible for containing and heating ores and smelting materials. The harsh conditions in high-temperature environments place extremely high demands on refractory materials in this area, which require strong resistance to high temperatures and erosion.

Customized physical and chemical indicators of zircon mullite bricks

Saiz: customizable

Weight: about 5kg/piece

Compressive strength at normal temperature: ≥100MPa

Load softening starting temperature: ≥1700℃

Apparent porosity: ≤18%

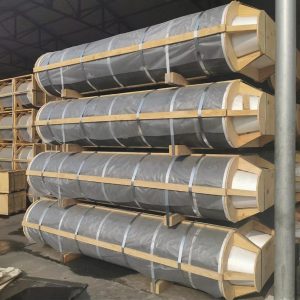

Refractory bricks shipped to Spain

Kumpulan Rongsheng

Kumpulan Rongsheng

WeChat

Imbas Kod QR dengan wechat