Silicon carbide powder is a hexagonal crystal, with stable chemical properties, high thermal conductivity, small thermal expansion coefficient, good wear resistance, and Mohs hardness of 9.5. It has black and green two basic varieties. Black silicon carbide powder has good toughness, it is widely used in the glass industry, ceramic industry, stone industry, refractory industry, iron industry, non-ferrous industry, and so on. Green silicon carbide powder has good self-sharpening, and is mostly used for processing hard alloy, titanium alloy,y, and optical glass, and also for honing cylinder liners and accurate grinding HSS tools.

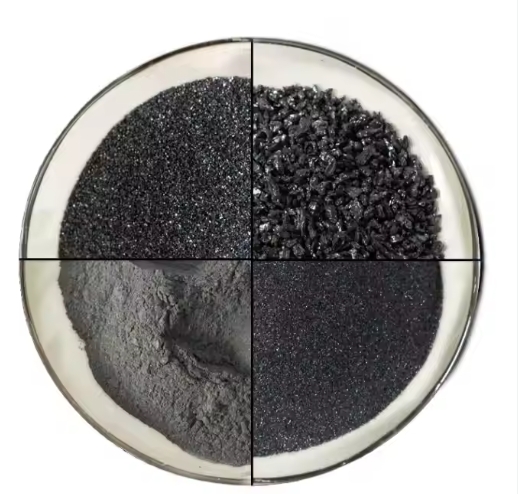

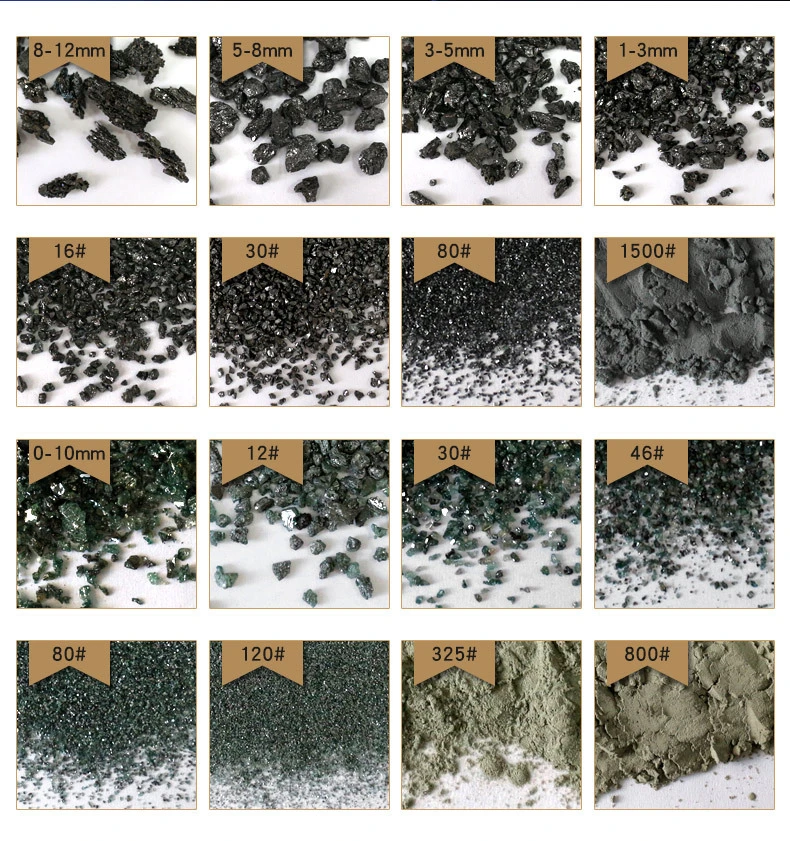

Black silicon carbide powder and green silicon carbide powder

According to different uses, silicon carbide can be divided into black silicon carbide and green silicon carbide.

Black silicon carbide: contains more than 99% SiC and is mainly used for refractory materials, abrasives, dan lain-lain.

Green silicon carbide contains more than 99.5% SiC and has higher purity. It is mostly used in ceramics and semiconductor manufacturing.

Technical parameter of silicon carbide raw material

| Color | Granularity range | Chemical Component % | Density g/cm3 | ||

| SiC | F.C | Fe2O3 | |||

| Black | F4~F90/P12~P100 | ≥98.6 | ≤0.2 | ≤0.4 | ≥3.12 |

| F100~F150/P120~P150 | ≥98.1 | ≤0.25 | ≤0.5 | ||

| F180~F220/P180~P220 | ≥97.2 | ≤0.3 | ≤0.55 | ||

| F230~F280/P240~P360 | ≥97.2 | ≤0.3 | ≤0.55 | ≥3.10 | |

| F320~F500/P400~P1000 | ≥97.0 | ≤0.35 | ≤0.6 | ||

| F600~F800/P1200~P1500 | ≥96.5 | ≤0.4 | ≤0.6 | ||

| F1000~F1200/P2000~2500 | ≥95.5 | ≤0.5 | ≤0.7 | ||

| Green | F4~F90/P12~P100 | ≥99.1 | ≤0.2 | ≤0.2 | ≥3.18 |

| F100~F150/P120~P150 | ≥98.6 | ≤0.25 | ≤0.45 | ||

| F180~F220/P180~P220 | ≥98.0 | ≤0.25 | ≤0.5 | ||

| F230~F280/P240~P360 | ≥98.0 | ≤0.3 | ≤0.5 | ≥3.15 | |

| F320~F500/P400~P1000 | ≥97.5 | ≤0.3 | ≤0.5 | ||

| F600~F800/P1200~P1500 | ≥97.0 | ≤0.35 | ≤0.5 | ||

| F1000~F1200/P2000~P2500 | ≥96.5 | ≤0.4 | ≤0.5 | ||

Basic characteristics of silicon carbide powder

High hardness and high wear resistance: Mohs hardness is as high as 9.2~9.5, making it an ideal wear-resistant material.

High thermal conductivity: The thermal conductivity is as high as 120~270 W/m·K, with excellent thermal conductivity.

High-temperature stability: Excellent high-temperature resistance, can be used stably for a long time in an environment above 1600℃.

High corrosion resistance: Strong resistance to acid and alkali corrosion, suitable for harsh chemical environments.

Excellent thermal shock stability: It can effectively resist thermal shock damage when the temperature rises or falls rapidly.

Controllable electrical properties: It has both conductivity and insulation and is widely used in the semiconductor field.

Application fields of silicon carbide powder

Refractory materials

SiC is an important raw material for manufacturing refractory bricks, Casflbles, and ceramic vessels due to its high temperature and corrosion resistance. It is widely used in high-temperature kiln linings in industries such as metallurgy, kaca, and cement.

Abrasives and cutting tools

SiC is used as an abrasive due to its high hardness to make tools such as grinding wheels, grinding discs, and grinding heads. It is also used to cut hard materials such as glass, ceramics, and gemstones.

Semiconductor materials

As a third-generation semiconductor material, SiC has the characteristics of wide bandgap, high breakdown electric field, and high thermal conductivity. It is widely used in electric vehicles, 5G communications, photovoltaic inverters,,s and other fields to manufacture power devices such as MOSFET, IGB, T and diodes.

Chemical equipment

SiC materials are highly resistant to corrosion, so they are used as heat exchangers, reactor linings, pum,p, and valve components in the chemical industry, especially for handling strong acids, strong alkalis and high-temperature corrosive media.

New energy technologies

In solar and wind power equipment, SiC is used as heat exchange elements and inverter devices. Its high efficiency and high durability provide a guarantee for the stable operation of new energy equipment.

Aerospace and military industry

SiC is used to manufacture high temperature-resistant and oxidation-resistant aerospace equipment parts, such as turbine blades and missile nose cones, due to its lightweight and high strength.

Kumpulan Rongsheng

Kumpulan Rongsheng

Hello,

I am interested in Siliciumcarbide Powder with 1-3mm diameter in particle diameter. Do you have a distributor within the european union? This would make the delivery easier! I am based in Germany.

Hello, we are very happy to receive your inquiry. Our business manager will contact you to discuss the delivery details of silicon carbide. Please check your email.