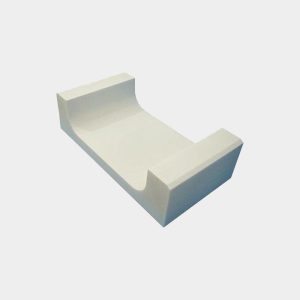

Sintered zirconium corundum bricks are made of imported high-purity raw materials, fused raw materials, ultra-fine powder, and composite admixtures through high-pressure forming and high-temperature sintering. The glass liquid has the characteristics of strong erosiveness, high-temperature resistance, good thermal shock stability, excellent high-temperature creep resistance, strong corrosion resistance to slag and glass liquid, etc., and is used in glass furnace lattices, small furnaces, working pools, domes and forehearths and other parts.

Technical parameter of sintered zirconium corundum brick

| Take | Rārangi whakaatu | ||

| AZS-16 | AZS-20 | AZS-32 | |

| Zo2 % | ≥16 | ≥20 | ≥32 |

| Fe2O3 % | ≤0.4 | ≤0.3 | ≤0.3 |

| Bulk Density g/cm3 | ≥2.9 | ≥3.0 | ≥3.2 |

| Apparent Porosity % | ≤18 | ≤17 | ≤17 |

| Te kaha o te makariri MPA | ≥90 | ≥95 | ≥100 |

| 0.2Mpa Refractoriness Under Load ℃ | ≥1650 | ≥1700 | ≥1700 |

Sintered AZS brick features

Sintered zirconium corundum bricks are also called ceramic-bonded aluminosilicon zirconium bricks. Compared with fused zirconium corundum bricks, the chemical composition of sintered zirconium corundum bricks is similar, but it has the advantages of containing no carbon, lower glass phase content, uniform structure, no shrinkage cavities, and good thermal shock stability and corrosion resistance.

Rongsheng Group

Rongsheng Group

WeChat

Matawai te Waehere QR me te wechat