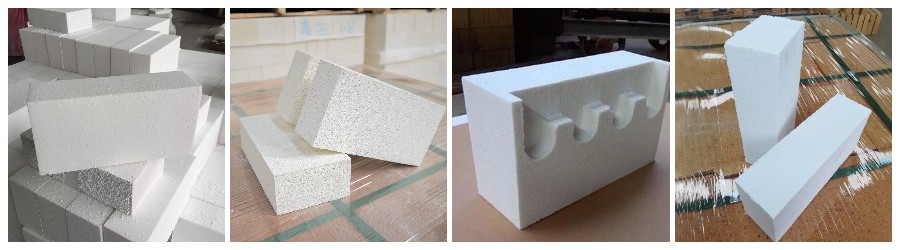

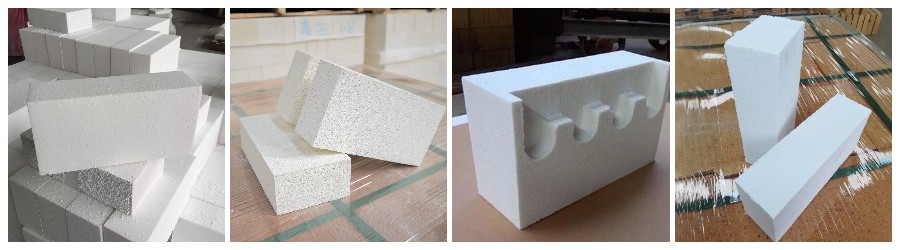

アルミナバブルレンガは使用温度が高く、高温でも優れた断熱性能を備えています。. 炉本体の軽量化において明らかな成果が得られます。, 構造を変える, 材料の節約, そしてエネルギーの節約.

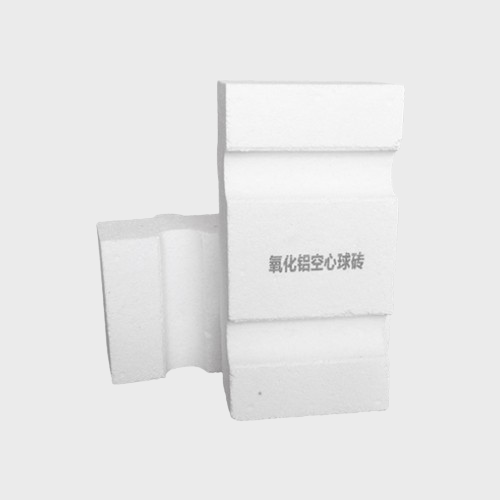

アルミナバブルレンガ

アルミナバブルレンガ

アルミナバブルレンガの技術パラメータ

| アイテム | 索引 |

| LQZ99-1.4 | LQZ99-1.6 | LQZ99-1.8 |

| アル2○3 % | ≥99 |

| SiO2 % | ≤0.3 |

| 鉄2○3 % | ≤0.2 |

| かさ密度 g/cm3 | 1.3~1.5 | 1.5~1.7 | 1.7~1.9 |

| 冷間圧壊強さ MPa | ≥6 | 10以上 | ≥12 |

| 熱伝導率(W/)(m・K) 高温面1000℃ | ≤0.9 | ≤1.1 | ≤1.2 |

| 永久線形変化率 % 1600℃×3H | ±0.3 |

| アイテム | 索引 |

| LQZ95-1.4 | LQZ95-1.6 | LQZ95-1.8 |

| アル2○3 % | ≥95 |

| 鉄2○3 % | ≤0.2 |

| かさ密度 g/cm3 | 1.3~1.5 | 1.5~1.7 | 1.7~1.9 |

| 通常の温度圧縮強度MPa | ≥8 | ≥12 | ≥16 |

| 熱伝導率(m・K) ホットフェイス1000℃ | ≤0.9 | ≤1.1 | ≤1.2 |

| 直線永久変化率 % 1600℃×3h | ±0.3 |

| アイテム | 索引 |

| LQZ90-1.4 | LQZ90-1.6 | LQZ90-1.8 |

| アル2○3 % | 90以上 |

| 鉄2○3 % | ≤0.2 |

| かさ密度 g/cm3 | 1.3~1.5 | 1.5~1.7 | 1.7~1.9 |

| 通常の温度圧縮強度MPa | 10以上 | ≥14 | 18歳以上 |

| 熱伝導率(m・K) 熱面1000℃ | ≤0.9 | ≤1.1 | ≤1.2 |

| 直線永久変化率 % 1600℃×3h | ±0.3 |

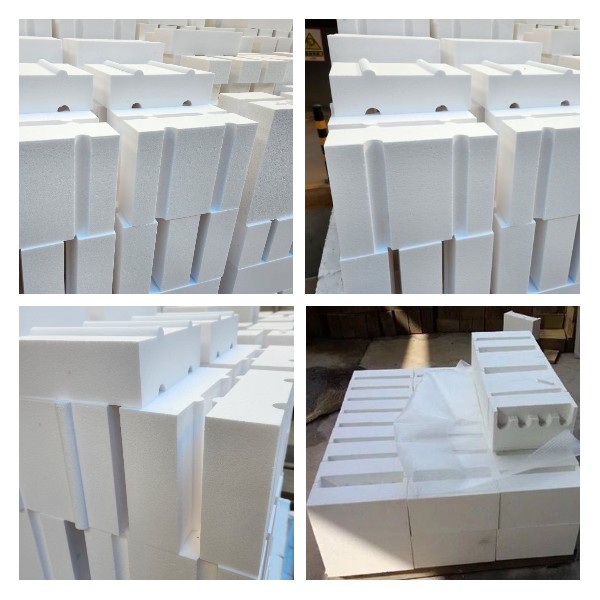

アルミナ中空玉煉瓦の塗布

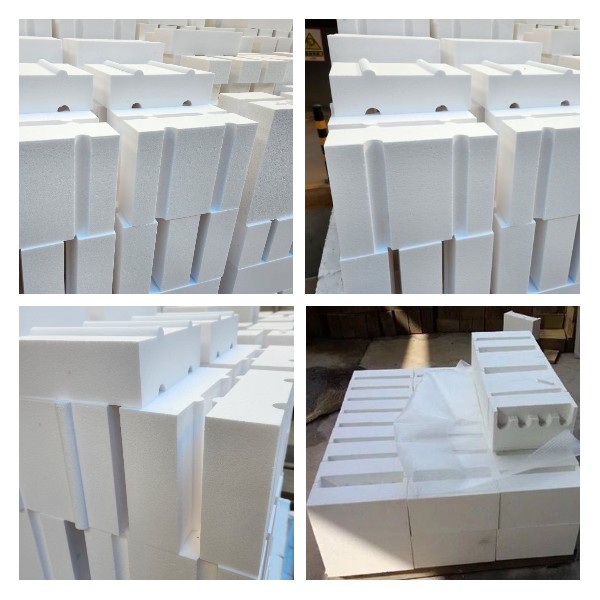

アルミナ中空断熱れんが

アルミナ中空断熱れんが

アルミナ中空ボール煉瓦の耐火性は 1750°C 以上に達することがあります。, 熱安定性が良い, 燃焼線の変化率が小さい, そして耐久性. 断熱性が高く、熱伝導率が低いのが特徴です。. アルミナ中空玉煉瓦は高温省エネ逆火炉で使用可能, シャトルキル, モリブデン線炉, タングステンロッド炉, 誘導炉, 窒化炉, 等.

アルミナ中空玉れんがの特徴

アルミナ中空玉レンガ

アルミナ中空玉レンガ

- 高温使用: 良好な熱安定性, まで 1750 度以上. 再燃焼ラインの変化率が小さく、使用時間が長い.

- 構造の最適化と炉の軽量化: 現在のところ, 高温耐性のある材料は、 重いレンガ 体積密度2.6~3.0g/cm. アルミナ中空ボールレンガはわずか1.1~1.5g/cm, 同じ1立方メートルの体積, アルミナ中空ボールレンガを使用すると、次のような重量を軽減できます。 1.1-1.9 トン.

- 素材の保存: 同じ動作温度を達成するには, 重いレンガを使用する場合, 価格はアルミナ中空ボールレンガの価格と同等です, しかし、大量の断熱耐火物も必要です. アルミナ中空玉煉瓦を使用する場合, 保存できます 1.1-1 立方メートルあたり. 使用する場合 9 大量の重いレンガ, 保存できます 80% 耐火断熱材の.

- 省エネ: アルミナ中空ボールは明らかな断熱特性と低い熱伝導率を備えています。. 優れた断熱役割を果たすことができます, 熱放散を減らす, 熱効率を向上させます, それにより省エネの目的を達成します.

栄生グループ

栄生グループ

微信

wechatでQRコードをスキャン