فوهة الانزلاق مغرفة هي نظام مهم للتحكم في إنتاج الصلب. إذا كان النظام يتسرب من الصلب أثناء الاستخدام, سيؤدي ذلك إلى تقييد الإنتاج المستقر والسلس بشكل خطير ويهدد سلامة الموظفين والمعدات. تحلل هذه الورقة العوامل المختلفة التي تؤثر على تسرب نظام لوحة بوابة الشريحة الحرارية مغرفة.

تحليل سبب تسرب الصلب من لوحة بوابة الشريحة الحرارية مغرفة

1. تسرب لوحة بوابة الشريحة الناتجة عن أسباب ميكانيكية

بسبب التشوه الجزئي للقوس أو استخدام بعض الينابيع, قوة التثبيت على كلا الجانبين غير متسقة, مما أدى إلى ضغط سطح غير متساو بين الطوب الشريحة, جانب واحد يخضع لقوة أكبر, والجانب الآخر يخضع لقوة أقل. عندما يتجاوز ضغط الفولاذ المنصهر ضغط السطح على جانبي الشريحة, سيدخل الصلب المنصهر بين سطحي الشريحة, مما تسبب في انقطاع الفولاذ أو تسرب الصلب.

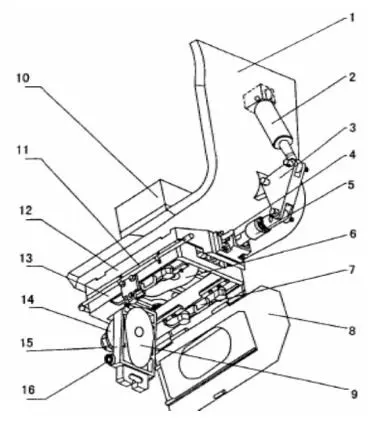

رسم تخطيطي ل لوحة بوابة الشريحة مغرفة: 1. جدار مغرفة; 2. اسطوانة هيدروليكية; 3. ترايبود; 4. يدعم; 5. سحب قضيب; 6. الشريحة العلوية; 7. جزء الضغط; 8. لوحة الحرس; 9. شريحة أسفل; 10. قرميد قاعدة مدخل الماء; 11. أنبوب الهواء البارد; 12. لوحة أسفل مربعة; 13. قوس; 14. دخول مدخل الماء السفلي; 15. عربة منزلق; 16. عربة منزلق العربة

بسبب سقوط شريط التمرير أو تخفيف الأكمام الدوارة السفلية, الضغط على سطح اللوحة غير كافٍ, والتي يمكن أن تتسبب بسهولة في حجب سطح اللوحة الفولاذ عند التحكم في التدفق أثناء العملية. كما يكثف تساقط سطح اللوحة, تزداد الفجوة بين لوحات الشرائح تدريجياً, وأخيرا يسبب تسرب الصلب. يؤدي انخفاض شريط التمرير إلى عدم قدرة العربة على الحفاظ على العملية الأفقية أثناء العملية, مما أدى إلى فجوات بين لوحات الشريحة; عندما يكون الأكمام الدوارة السفلى فضفاضة, سوف تغرق لوحة الشريحة السفلى, مما أدى إلى فجوات بين أسطح اللوحة.

تسرب الفولاذ الناجم عن مادة لوحة بوابة الشريحة الحرارية مغرفة

⑴ عند صب الفولاذ المعالج بالكالسيوم أو الصلب العالي المانغاني, مدخل الماء العلوي والطوب الشريحة لهما مقاومة تآكل سيئة, يتوسع مدخل الماء والشرائح بسرعة, ويصبح السكتة الدماغية الفعالة للشريحة أصغر, والتي يمكن أن تتسبب بسهولة في أن يكون تدفق الصب خارج نطاق السيطرة أو سطح اللوحة لكسر الصلب.

⑵ الطوب الشريحة العلوي والسفلي لهن قوة درجات حرارة منخفضة أو مقاومة سيئة ل “صدمة حرارية”. قبل سكب الشريحة, عندما تكون درجة حرارة سطح اللوحة (~ 350 ℃) يبدأ في صب الفولاذ, يتلامس ثقب صب فجأة مع الصلب المنصهر بدرجة الحرارة العالية (~ 1580 ℃) ويخضع قوي “صدمة حرارية”. ينتج الجزء الخارجي من الفتحة الشد إجهاد الشد يتجاوز قوة الشريحة, تشكيل تشققات شعاعية تتمحور على الفتحة المصب. ظهور الشقوق يسارع التآكل الكيميائي, وفي نفس الوقت, تفاعلات التآكل الكيميائي تعزز تشكيل وتوسيع الشقوق (في الحالات الشديدة, سوف تتسرب من الصلب وتسرب الصلب).

⑶ الأسطح العاملة للشرائح العلوية والسفلية لها مقاومة ارتداء درجة حرارة عالية (تحتوي مادة الشريحة على مقاومة أكسدة رديئة أو أن الشرائح العلوية والسفلية لها تناسب ضعيف, الفجوة كبيرة جدا, ويتسبب الهواء المستنشق أثناء سكب الصلب في أن يتأكسد سطح الانزلاق ويتم تقليل القوة), والسطح المنزلق سهل “خشن”. بعد التسلل إلى الصلب المنصهر, ال “خشن” يتم تفاقم الظاهرة عند الدفع والسحب, وتزداد مقاومة الاحتكاك في لوحة الشريحة. في الحالات الشديدة, قد يحدث تسرب الصلب بين الأسطح المنزلق. المواد الحرارية المستخدمة في لوحة الشريحة تتلامس مع الصلب المنصهر بالدرجة الأولى في درجة الحرارة والخبث أثناء العملية, وتحدث سلسلة من التفاعلات الكيميائية, تسبب التآكل الكيميائي.

تسرب من الصلب من لوحة بوابة الشريحة الملاهي الناتجة عن تشغيل غير لائق

⑴ تدوين عملية التجميع, هناك الأسباب التالية بشكل أساسي.

① بعد تجميع الفوهة العلوية, يجب خبز الفوهة السفلية لزيادة القوة بين الفوهة العلوية والطوب المقعد, لتجنب الضغط على الفوهة العلوية في لوحة الشريحة العلوية أثناء الاستخدام دون الخبز, مما أدى إلى فجوة بين الفوهة العلوية ولوحة الشريحة.

② عندما يتم تثبيت وسادة الطين على لوحة الشريحة العلوية, بسبب الفرق في القيمة المرئية للفجوة, لوحة الطين صغيرة جدًا أو أكثر من اللازم. عندما تكون لوحة الطين صغيرة جدًا, هناك فجوة بين الفوهة العلوية ولوحة الشريحة العلوية, والتي قد تسبب تسرب الصلب بين الفوهة العلوية ولوحة الشريحة العلوية أو التثبيت الفولاذ بين أسطح اللوحة. هذا النوع من تسرب الصلب أكثر ضررًا. بعد حدوث تسرب في المرحلة المبكرة, يجب التعامل معها في أقرب وقت ممكن لتجنب تسرب الصلب من جميع الجوانب في المرحلة اللاحقة, حرق براغي ربط آلية وحرق الآلية; عندما تكون لوحة الطين أكثر من اللازم, من السهل أن تتسبب في كسر سطح لوحة الشريحة. أثناء عملية صب, سوف تشكل الصلب المنصهر المشابك الصلب عند الشقوق, وسوف يحدث تسرب الصلب بعد سحب مشابك فوهة المياه عدة مرات للتوسع.

③ قوة درجات الحرارة العالية لبنة مقعد الفوهة منخفضة. عند استخدام اختيار هوائي لتغيير حرارة الطوب الفوهة العلوية من المغرفة, غالبًا ما يضر رأس الاختيار الهوائي لبنة المقعد, مما تسبب في توسع لبنة المقعد في القطر والفجوة بين لبنة المقعد والطوب الفوهة العلوية لزيادة. عند سكب الصلب المنصهر, الصلب المنصهر يشكل دوامة عند الطوب مقعد. تحت تأثير تجوب الصلب المنصهر, الفولاذ المنصهر يخترق الفجوة بسهولة, تسبب تسرب الصلب حول الطوب الفوهة العلوية.

④ رشقات قرميد الفوهة السفلى أثناء الاستخدام. عندما يتعرض لبنة الفوهة السفلية للصلب, سيكون لها شقوق أفقية تحت تأثير الإجهاد الحراري. تحت عمل ضغط الصلب المنصهر, تتوسع الشقوق تدريجيا إلى الشقوق, ويتسرب من الصلب المنصهر منهم. في الحالات الشديدة, المادة الحرارية تحت فترات كسر الكراك بسبب ثقلها وضغط الصلب المنصهر.

⑵ عندما يتم سكب الصلب المنصهر, الطبقة الملبدة من رمال الصرف سميكة للغاية. عندما يتم فتح لوحة الشريحة بالكامل, تكسر الطبقة الملبدة ويظهر الفولاذ عندما يتدفق, مما تسبب في التمسك بعجلة العربة المنزلق للصلب. أثناء عملية صب, الصلب العصي يدمر توازن الضغط في الآلية, يزيد الفجوة على سطح اللوحة, ويسبب حوادث تسرب الصلب.

⑶ تدوين عملية الإنتاج, بسبب حادث تدفق واحد من البليت المربع, كان وقت الرسم الصلب لفترة طويلة, كانت المغرفة الكبيرة نصف تدفق تلقي لفترة طويلة, وكثيرا ما تم فتح فوهة الانزلاق وإغلاقها, مما أدى إلى تآكل خطير لسطح اللوحة. عندما كانت الفوهة المنزلق نصف تدفق, تم البحث بقوة عن لبنة الشريحة السفلية بواسطة الفولاذ المنصهر بسبب اعتراض الصلب المنصهر. بعد وقت طويل, سيتم تشكيل الأخاديد على الطوب الشريحة, وستظهر الأخاديد على شكل حدوة حصان على سطح الشريحة السفلية. عندما تم إغلاق المغرفة, الصلب المنصهر المكثف في الأخدود, مما أدى إلى تقطيع الصلب بين الشرائحين. فضلاً عن ذلك, كان عدد أوقات التحكم في التدفق متكررة نسبيًا, وكان اتجاه شطورة الصلب سريعًا نسبيًا, الذي كان عرضة لحوادث التسرب الفولاذية في المرحلة الأخيرة من الصب (شكل 2).

مجموعة رونغ شنغ

مجموعة رونغ شنغ

وي شات

مسح رمز الاستجابة السريعة باستخدام wechat