Alümina Magnezya Karbon Tuğlası, korozyon direncinin avantajlarına sahiptir, taşlama direnci, Erimiş çelik ovmaya karşı iyi direnç, Güvenli Kullanım, daha az çelik ve cüruf, kolay ambalaj, ve benzeri.

AMC refrakter tuğla tanıtın

Alümina-Magnezi Karbon Tuğlaları, AMC tuğlaları olarak adlandırılır, Magnezya gibi hammaddelerden yapılmış yanmamış refrakter tuğlalar, yüksek alüminyum agregatlar, ve ezme yoluyla karbon malzemeleri, Karıştırma, şekillendirme, ve kurutma süreçleri.

Alüminyum magnezyum karbon tuğlasının parametresi

| Dizin Öğe | RS-A | RS-80 | RS-85 | RS-88 | |

| MgO | % | 86 | 85 | 88 | 90 |

| Al2O3 | % | 5 | 7 | 6.5 | 6.5 |

| SIO2 | % | 3.2 | 4 | 2.4 | 1.2 |

| Cao | % | 1.6 | 1.5 | 1.3 | 1.2 |

| Fe2o3 | % | 3.7 | 1.7 | 1.4 | 1.0 |

| Görünür gözeneklilik | % | 16~ 20 | 17 | 17 | 17 |

| Yoğunluk | g / cm3 | 2.85~ 3.0 | 2.93 | 2.93 | 2.94 |

| Soğuk kırma gücü | Mpa | 41 | 50 | 50 | 55 |

| 0.2Yük Refraktorisity altında MPA | ℃ | ≥ 1550 | 1610 | 1650 | 1700 |

| Termal şok direnci(1100℃,su,söndürme, döngü) | 3~ 6 | 3~ 6 | 3~ 6 | 3~ 6 |

Alümina-Magnezi Karbon Tuğla Uygulaması

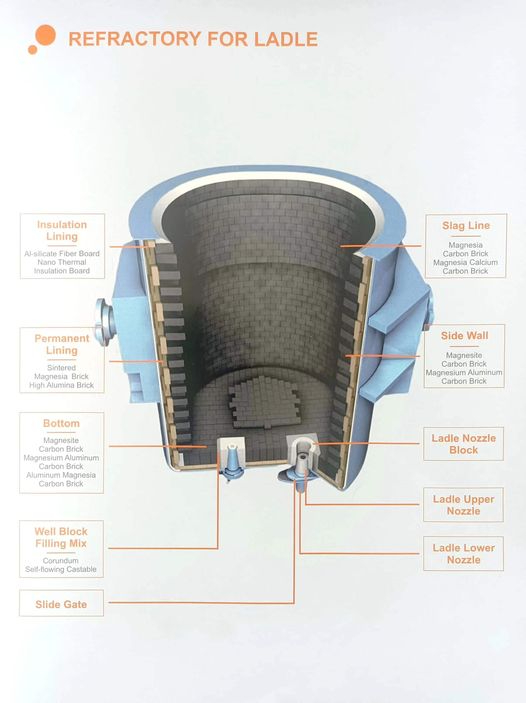

Alümina-Magnezi Karbon Tuğlaları Korozyon Direnci Avantajları, taşlama direnci, dengeli erozyon, Güvenli Kullanım, daha az çelik ve cüruf boyaması, ve kolay ambalaj. Alümina Magnezya Çelik Kepçe için Karbon Ateş Tuğlası Esas olarak zorlu koşullarda kullanılan çeliğin astarı için kullanılır. Erimiş havuz bölümünde kullanılan çelik kepçe için refrakter alümina magnezya karbon tuğlaları ve sürekli döküm büyük tundish ve fırının dışındaki rafine paketi alt kısmı için karbon tuğlaları.

Rongsheng Grubu

Rongsheng Grubu

WeChat

QR Kodunu wechat ile tarayın