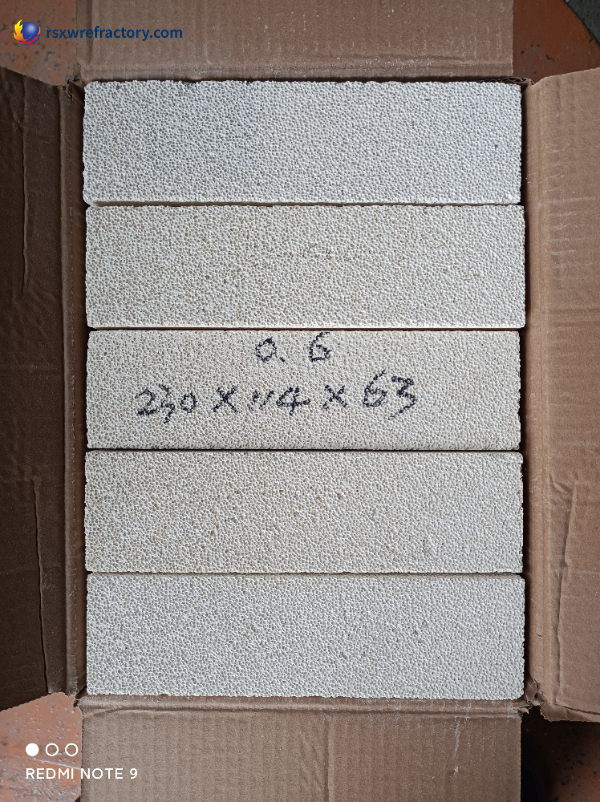

In the refractory insulation material industry, JM28 bricks have become an ideal choice for lining insulation of high-temperature kilns, industrial heating furnaces, annealing furnaces and other equipment due to their excellent thermal insulation performance, excellent thermal shock resistance and lightweight, and high strength. Our company recently completed the large-scale production of a batch of JM28 insulation bricks and has successfully shipped them to customers.

Product features of JM28 insulation bricks

- Uitstekende thermische isolatieprestaties: Low thermal conductivity can effectively reduce heat loss and improve the thermal efficiency of the kiln.

- High temperature resistance: It can work stably in a high temperature environment of 1250°C for a long time.

- High strength and low volume density: Under the premise of ensuring strength, the load of kiln equipment is greatly reduced.

- Good thermal shock resistance: It can withstand frequent temperature changes without cracking or peeling.

- Accurate size: Easy installation, tight splicing, and improved overall insulation effect.

JM28 brick production process

Raw material preparation

High-purity alumina powder and high-quality clay are selected as the main raw materials to ensure the chemical stability and high-temperature resistance of refractory bricks.

Mixing and molding

Use an automated mixing system to evenly mix the raw materials and form them through high-precision pressing equipment, so that each brick has high density and good strength.

Drying and firing

Adopt advanced high-temperature tunnel kilns to accurately control the firing temperature and time to ensure the complete sintering of the brick body and improve the high-temperature resistance and structural stability of the product.

Testing and packaging

Each batch of products must undergo a series of strict quality inspections such as size inspection, thermal conductivity test and compressive strength test before leaving the factory. The packaging adopts anti-collision and moisture-proof design to ensure the integrity of the product during transportation.

Wide application of JM28 insulation bricks

- High-temperature industrial kilns: such as glass kilns, ceramic kilns, tunnel kilns, enz.

- Heating furnaces and annealing furnaces: high-temperature heating equipment used in the steel, petrochemical, en andere industrieën.

- Electric furnace lining: as the insulation layer of the electric furnace, it improves thermal efficiency and extends the service life of the furnace lining.

Rongsheng -groep

Rongsheng -groep

Wechat

Scan de QR -code met WeChat