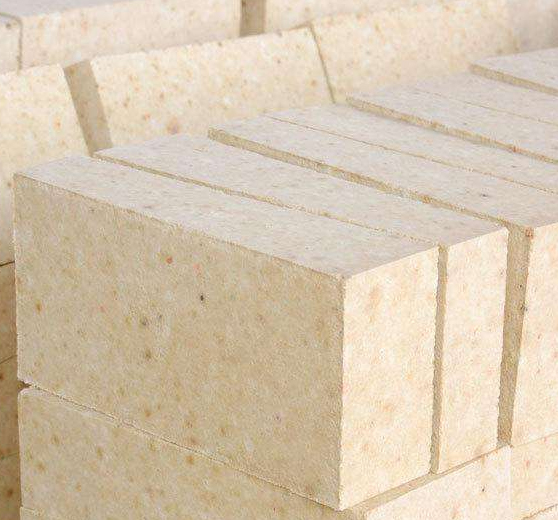

Anti-stripping high-alumina brick is a fired product made of high-alumina bauxite clinker and synthetic materials containing ZRO2 as raw materials, and is formed by high pressure according to a certain ratio. The product has strong anti-stripping ability and the properties of resistance to erosion by potassium, sodium, sulfur, chlorine, and alkaline salts, as well as low thermal conductivity. It is an ideal material for the transition zone and decomposition zone of the cement kiln. The remarkable characteristics of anti-stripping high-alumina refractory bricks are good thermal shock resistance and strong environmental adaptability. They are mostly used in the rotary preheating zone or decomposition furnace, and grate cooler, and other parts.

Anti-stripping high alumina brick introduction

Anti-stripping high-alumina brick is a new type of high-alumina material specially produced to solve the problem of cement kiln lining. It has excellent thermal shock stability, high load softening temperature, high temperature strength, alkali and clinker erosion resistance, high temperature wear resistance, anti-stripping, anti-scaling, anti-ringing, and low thermal conductivity. It has been widely used in my country’s new dry kiln, Lipo kiln, and wet kiln. The parts used include kiln door cover, ascending flue, cooling zone, transition zone, cooler rear wall and side wall, and curved beam top. It has been successfully applied in almost all parts of the kiln. Anti-stripping high-alumina bricks have been successfully used in relevant parts of cement kilns and in the regenerator of large float glass kilns, replacing traditional magnesia-chrome bricks, which not only prolong the service life of the kiln but also eliminate chromium pollution. فضلاً عن ذلك, the firing temperature of anti-stripping high-alumina bricks is about 300℃ lower than that of magnesia-chrome bricks, and the energy-saving effect is considerable.

Physical and chemical indicators of anti-stripping high alumina bricks

| مشروع | فِهرِس | |

| GKBL70 | KBL75 | |

| آل2يا3 % | ≥70 | ≥75 |

| زرو2 % | ≥6.0 | / |

| الحديد2يا3 % | ≤1.5 | ≤1.5 |

| الكثافة الظاهرية جم / سم3 | ≥2.55 | ≥2.6 |

| المسامية الظاهرة % | ≥22 | ≥20 |

| Normal temperature compressive strength MPa | ≥60 | ≥70 |

| 0.2MPa Load softening start temperature ℃ | ≥1470 | ≥1520 |

| Thermal shock stability times 1100℃ water cooling | ≥25 | ≥20 |

Features of anti-stripping high alumina bricks

(1) Strong resistance to alkali corrosion;

(2) Sufficient thermal shock stability and high temperature resistance;

(3) Certain mechanical strength and friction resistance;

(4) Suitable load softening temperature for kiln skin and long service life.

Anti-stripping high alumina bricks application

Anti-stripping high-alumina bricks are used in large rotary kilns; the top of the kiln head cover is paved with anti-stripping high-alumina bricks. Specific location

Anti-stripping high-alumina bricks are used in the firing zone of wet short kilns; the firing zone and transition zone of wet short kilns are paved with anti-stripping high-alumina bricks. Traditional wet staggered masonry is used.

The application of anti-stripping high-alumina bricks in cement kilns; the back wall and side wall of the grate cooler, the transition zone and the vicinity of the transition zone, the cooling zone, the decomposition zone, the kiln door cover, and the kiln mouth.

The application of anti-stripping high-alumina bricks in the pre-decomposition kiln system; the decomposition furnace, smoke chamber, and other parts extend from the end of the transition zone to the end of the kiln. According to the production characteristics of various kilns, the parts that cannot be borne by alkali-resistant insulation bricks are all paved with anti-stripping high-alumina bricks.

مجموعة رونغ شنغ

مجموعة رونغ شنغ

وي شات

مسح رمز الاستجابة السريعة باستخدام wechat