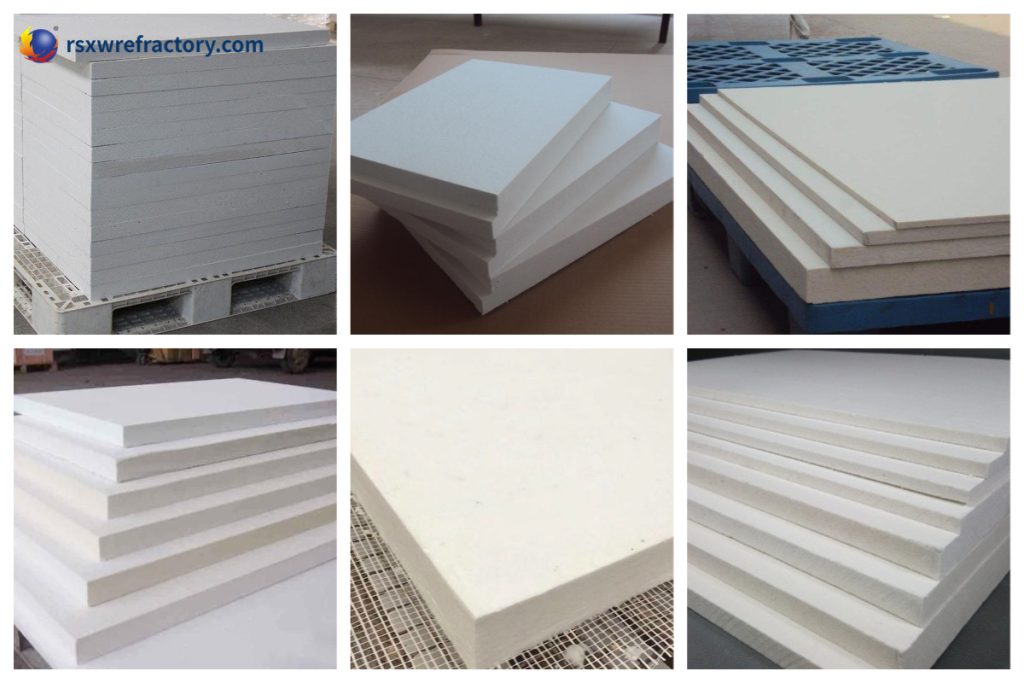

The ceramic fiber board is a refractory material made of aluminum silicate fiber board. In addition to its hard texture, ceramic fiber board has excellent toughness and strength and is resistant to wind erosion. Heating does not expand, is lightweight, has convenient construction, easy to shape or cut, is an ideal energy-saving material for kilns, pipes, and other thermal insulation equipment.

Technical parameters of ceramic fiber board

| Item | Index | ||||||

| Die plate | Mechanism board | Fire baffle | |||||

| Classification temperature | 1260 | 1260 | 1400 | 1260 | 1400 | ||

| Brand | XB126M | XB126A | XB126B | XB140A | XB140B | XB126D | XB140D |

| Permanent Linear Change Rate % ℃×24h | ≤-4 1000 | ≤-3 1000 | ≤-3 1100 | ≤-3 1200 | ≤-3 1350 | ≤-3 1100 | ≤-3 1200 |

| Thermal Conductivity W/(m·K) 500℃ | ≤0.135 | ||||||

| Moisture content % | ≤1.5 | ||||||

| Organic content % | ≤5 | ||||||

| Bulk density kg/m3 | 400 | 300 | 320 | ||||

| Size mm | Die plate 900×600×25/30;Other 900×600×25/50 | ||||||

Functions of ceramic fiber board

- Ceramic fiberboard high-temperature insulation: Ceramic fiberboard can maintain good thermal insulation performance in high-temperature environments, prevent heat from being transferred outward, and play a role in protecting equipment and the processing environment.

- Ceramic fiberboard is resistant to chemical corrosion: Ceramic fiberboard is made of inorganic materials and is not easily corroded and damaged in harsh environments such as chemical reactions or acid rain. Therefore, it is widely used in equipment in some chemical and building materials industries.

- Ceramic fiberboard has excellent insulation performance: Ceramic fiberboard has good electrical insulation performance and will be widely used in power, electronics and other fields.

- Ceramic fiberboard is light and durable: Ceramic fiberboard has low density and good strength, can maintain good physical properties during long-term use, and is also more convenient to process and not easy to break.

Application range of ceramic fiberboard

- Wall lining of high-temperature reaction equipment and heating equipment (such as chemical industry).

- Industrial furnace doors, top cover seals, kiln linings.

- Power industry boilers, steam turbines, and nuclear power insulation.

- Fire insulation for the construction industry and fire doors.

- Fire insulation forthe shipbuilding industry.

Rongsheng refractory insulation material manufacturer

Rongsheng is a refractory material factory that can produce refractory bricks, insulation bricks, refractory castables, refractory cement, ceramic fiber blankets and ceramic fiberboards, which are our main selling products, and we can customize them according to the drawings and physical and chemical indicators you can provide. Please feel free to contact us!

ரோங்ஷெங் குழு

ரோங்ஷெங் குழு

WeChat

wechat மூலம் QR குறியீட்டை ஸ்கேன் செய்யவும்