Magnesia carbon brick effectively utilizes the strong slag erosion resistance of magnesia and the high thermal conductivity and low expansion of carbon and compensates for the biggest disadvantage of poor spalling resistance of magnesia. It has good high-temperature resistance, strong slag resistance, good thermal shock resistance, and a low high-temperature creep rate.

MgO-C bricks introduce

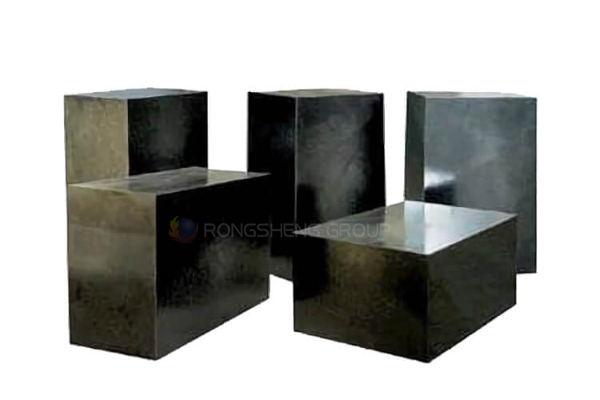

Magnesia carbon bricks are made of magnesia, dead-burned magnesia, fused magnesia, high-purity magnesia, and high-quality graphite and bauxite additives. The price and performance of magnesia carbon bricks have a great relationship with the graphite content in the bricks. As the graphite content increases, the strength of the brick decreases, the thermal expansion rate decreases, and the residual expansion rate increases.

Parameter of magnesia carbon brick

| Item | Index | ||||

| MT10A | MT12A | MT14A | MT16A | MT18A | |

| MgO % | ≥80 | ≥78 | ≥76 | ≥74 | ≥72 |

| C % | ≥10 | ≥12 | ≥14 | ≥16 | ≥18 |

| Apparent porosity % | ≤4 | ≤4 | ≤3.5 | ≤3.5 | ≤3.0 |

| Bulk density g/cm3 | ≥3.02 | ≥2.97 | ≥2.95 | ≥2.92 | ≥2.89 |

| Cold Crushing Strength MPa | ≥40 | ≥40 | ≥38 | ≥35 | ≥35 |

| High temperature flexural strength MPa 1400℃×0.5h | ≥6 | ≥6 | ≥10 | ≥8 | ≥10 |

Application of magnesia carbon bricks

Magnesium carbon bricks are mainly used for the lining of converters, AC electric arc furnaces, DC electric arc furnaces, and slag lines of ladles.

Rongsheng тобы

Rongsheng тобы

WeChat

wechat арқылы QR кодын сканерлеңіз