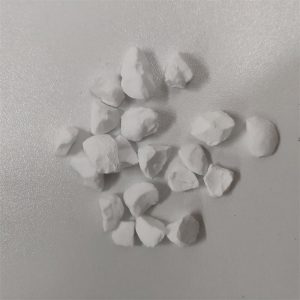

High alumina grog is an important ore. Refractory Bauxite is commonly used to process refractory aggregates and powders among amorphous refractory materials. In some refractory materials industries, the proportion of bauxite clinker ranges from 15% to 95%. It can be said that the quality of bauxite clinker determines the quality of the product.

High alumina grog process

To obtain high-quality bauxite clinker, a new bauxite calcination process is proposed: raw material entering the factory → storage → crushing → grinding → desalinization → wet homogenization → filtering → slurry → extrusion Forming → drying → calcining → crushing → finished product.

How do we identify the quality of refractory bauxite?

- Check the mineral composition of bauxite. The main chemical components of bauxite are Al2O3, SiO2, Fe2O3, and TiO2, accounting for about 95% of the total components. The secondary components are CaO, MgO, KO, Na2O, MnO2, organic matter, and trace components.

- Identification of alumina clinker. To identify alumina clinker, take samples for physical and chemical analysis. Through physical and chemical analysis, try to select alumina clinker with high aluminum content and few impurities. Impurities such as TiO2, K2O, and CaO must meet the index requirements. These impurities will cause the liquid to phase increase, which affects the high-temperature mechanical properties of the alumina clinker. Body density and water absorption are also very important indicators, especially water absorption, which reflects whether the bauxite clinker is completely calcined. If the calcining is incomplete, under-burned materials will be brought in (under-burned materials are more harmful to the product, and there are under-burned materials. , indicating that the first and second stages of sintering are not fully reacted, and the volume shrinkage and expansion are not completed thoroughly. If undersintered materials are used, large volume changes will be brought to the product), which will seriously affect product performance.

- Direct observation. Observe the appearance. If it is whitish, blue, or off-white, the aluminum content is high; if it is brownish-yellow or light red, it contains a lot of iron; if you observe the cross-section, if it is dense and has no visible pores, it means that the bauxite is completely calcined. There is no shortage of fuel.

The main uses of bauxite

(1) Aluminum smelting industry. Used in national defense, aviation, automobiles, electrical appliances, chemicals, daily necessities, т.б.

(2) Precision casting. Alumina clinker is processed into fine powder and made into casting molds and then precision cast. Used in military, aerospace, communications, instrumentation, machinery, and medical equipment sectors.

(3) Used in refractory products. High alumina clinker has a refractoriness of up to 1780°C, strong chemical stability, and good physical properties.

(4) Aluminum silicate refractory fiber. It has the advantages of lightweight, high-temperature resistance, good thermal stability, low thermal conductivity, small heat capacity, and resistance to mechanical vibration.

(5) Abrasive materials, the ceramic industry, and the chemical industry can produce various aluminum compounds.

(6) Using magnesia and bauxite clinker as raw materials, and adding appropriate binding agents, the effect of casting the overall lining of steel drums is very good.

Rongsheng тобы

Rongsheng тобы

WeChat

wechat арқылы QR кодын сканерлеңіз